The Problem

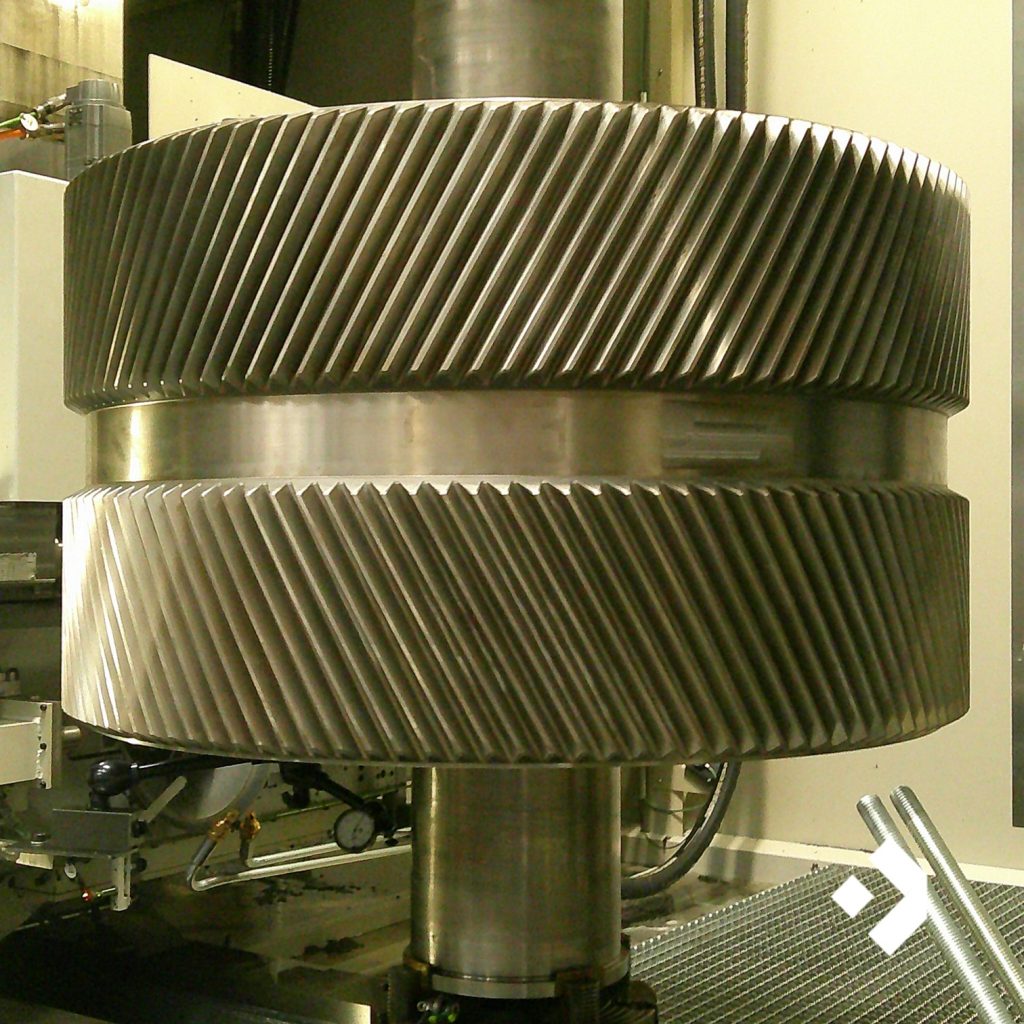

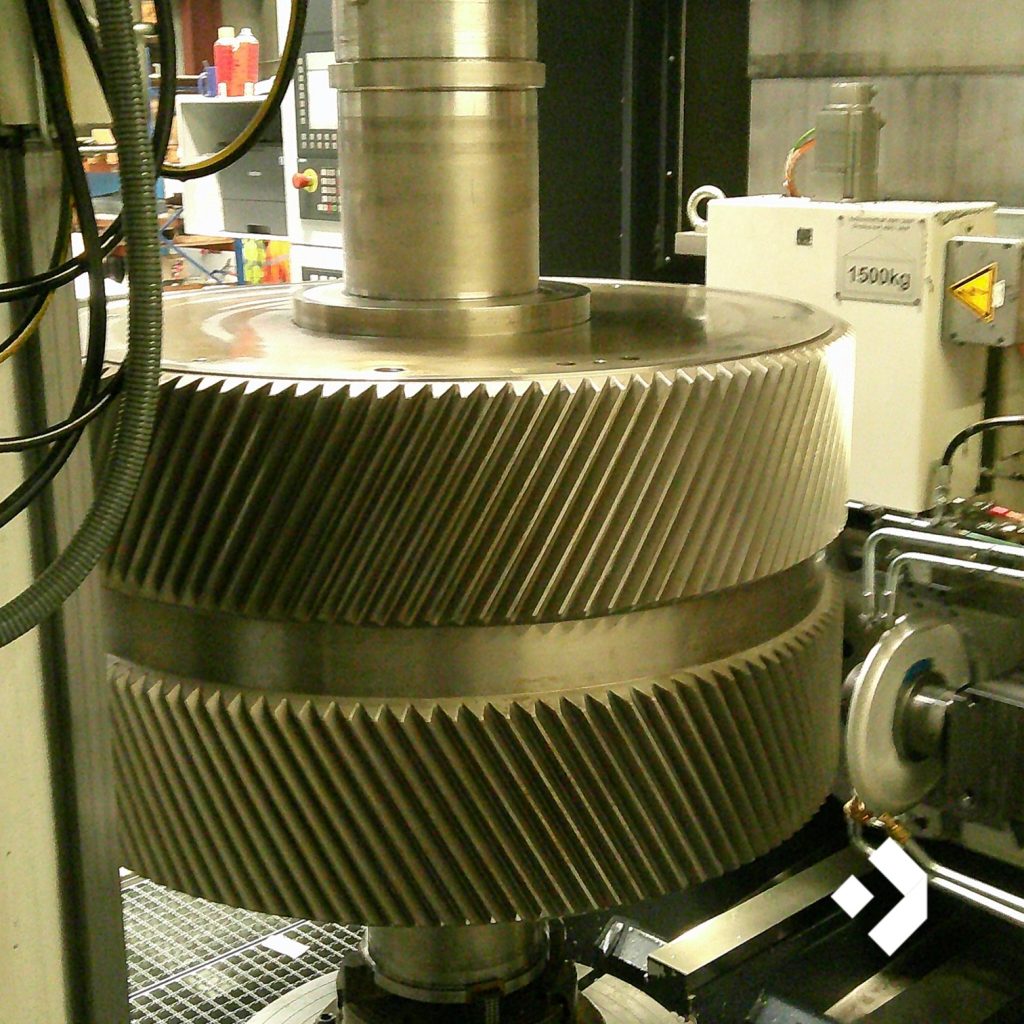

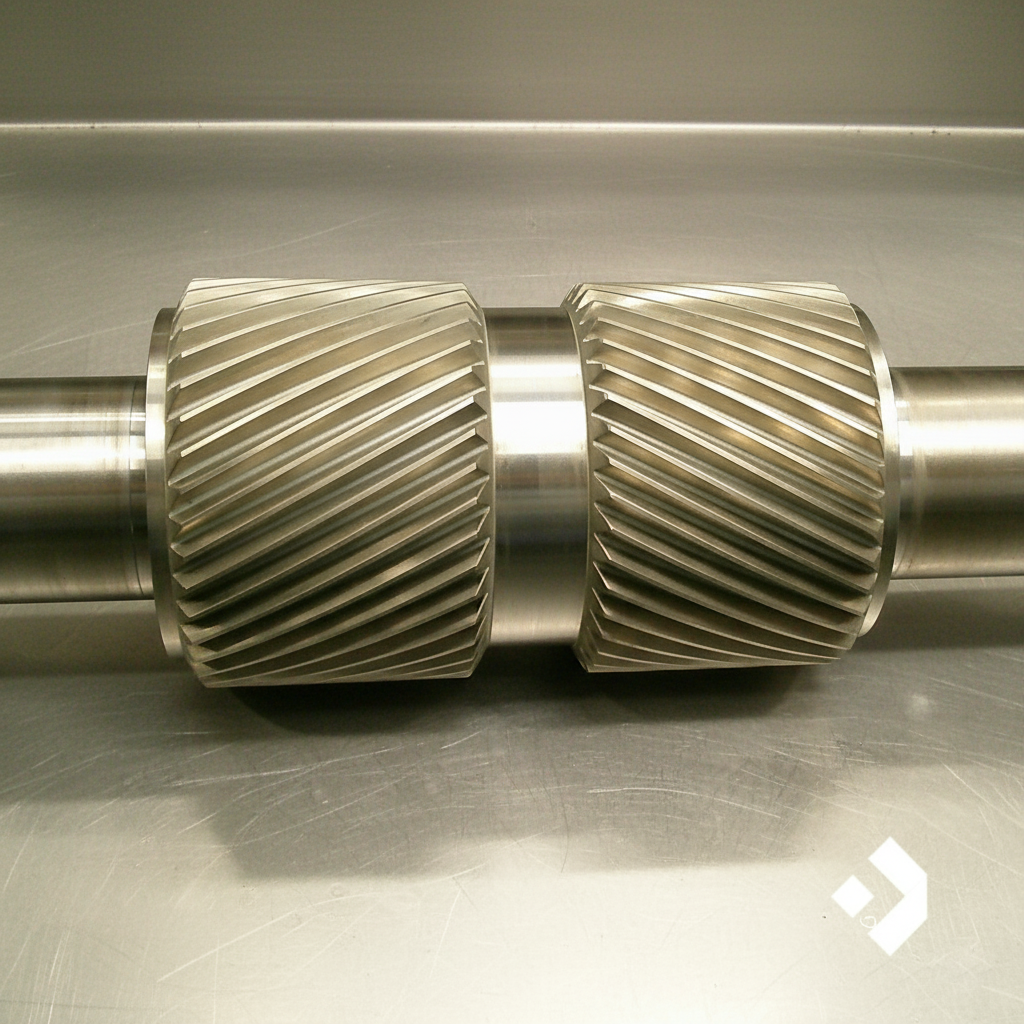

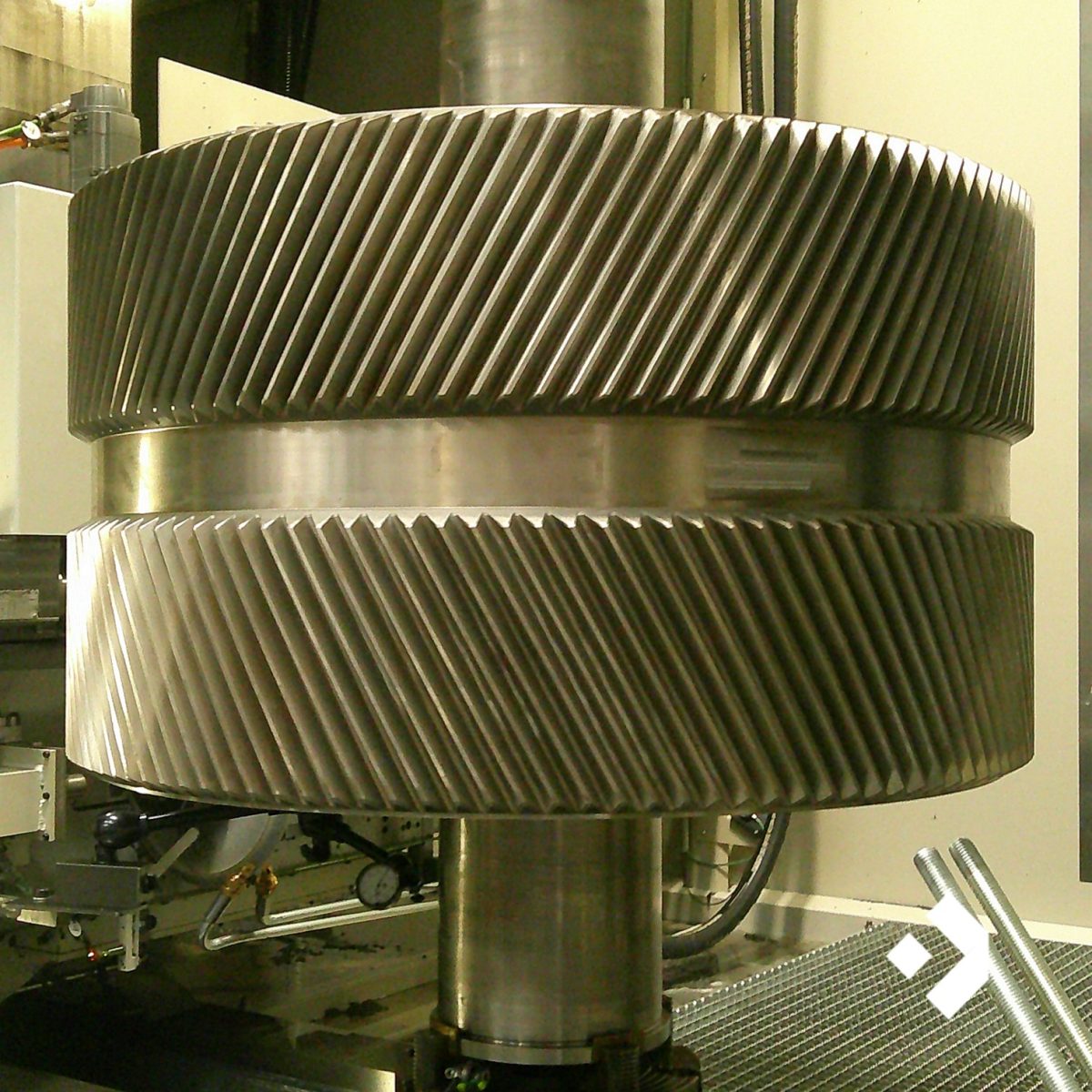

A client in the Power Transmission sector needed urgent support with gearwheel and pinion rotors from a gearbox. These components required precise inspection to ensure they met tight tolerances, which is critical for performance and reliability in high-demand applications. The challenge was to deliver high-accuracy inspection results within a tight 2-week timeframe.

The Solution

Lamond and Murray were chosen for the job due to their reputation and previous successful work with a related company. Using the P1480G profile gear grinding machine, the team carried out tooth geometry inspections with an on-board inspection probe. This advanced technology enabled them to measure the gearwheel with a precision of 0.007mm, providing the customer with detailed inspection graphs that visually demonstrated the accuracy of the results.

What stood out in this project was Lamond and Murray’s ability to leverage their machinery not just for manufacturing, but also for high-precision inspection, offering clients both confidence and clarity.

The Result

The customer was extremely satisfied with the quality and transparency of the work. As a result, they have begun recommending Lamond and Murray to other potential clients, expanding the company’s reach through word-of-mouth and industry trust.