The Problem

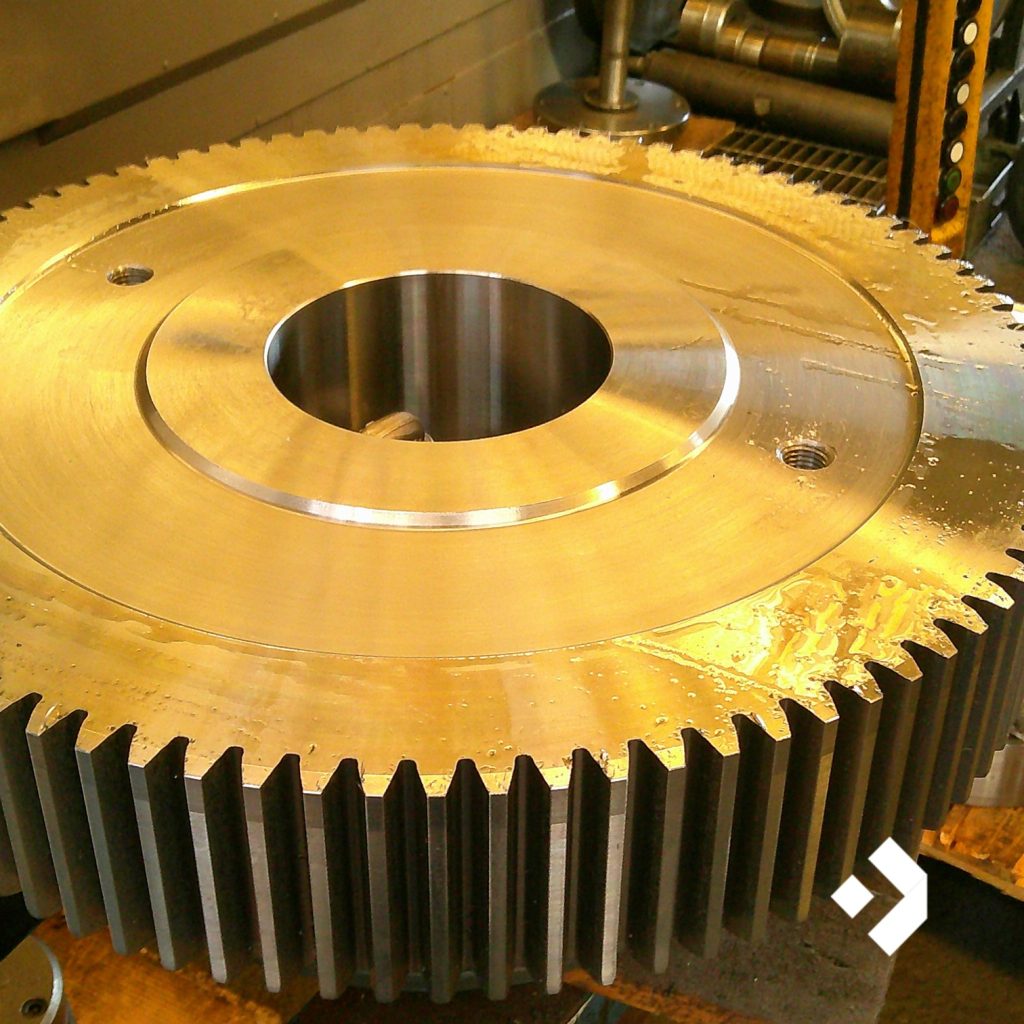

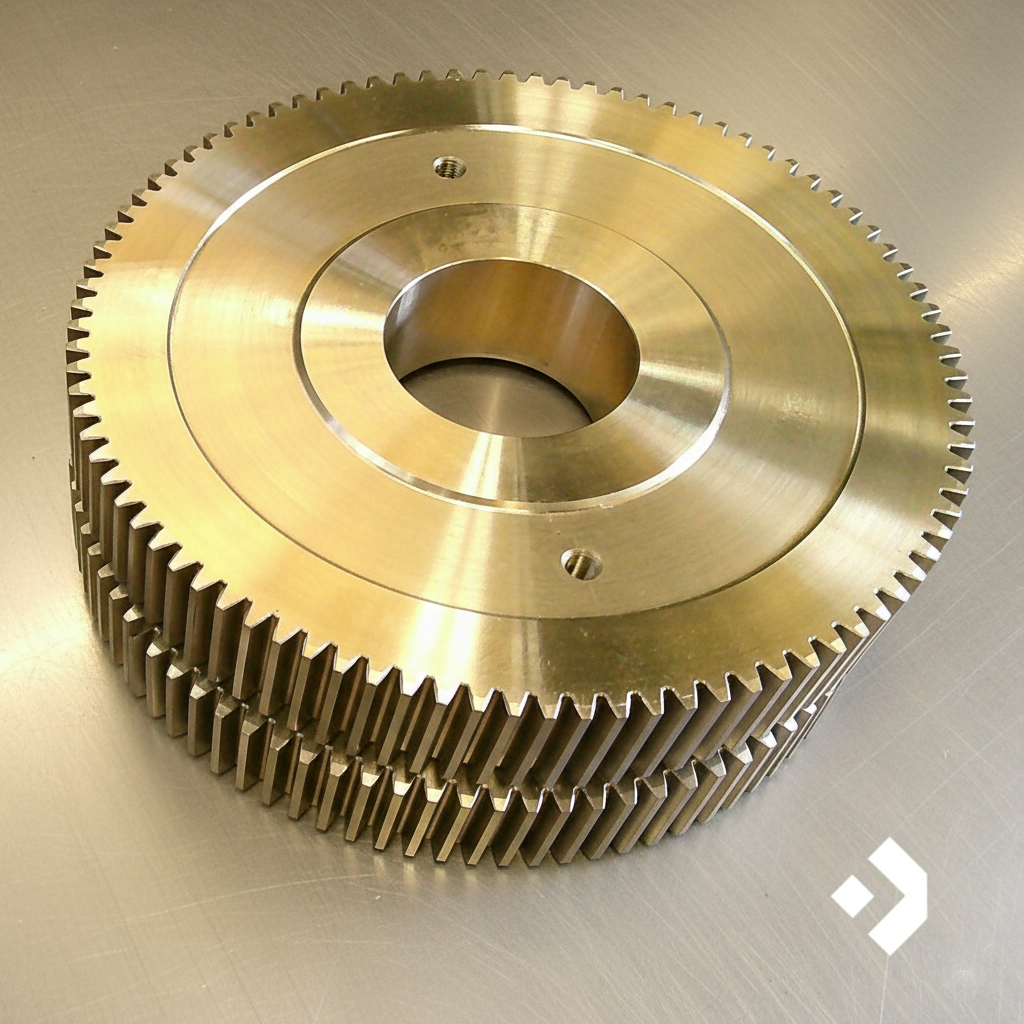

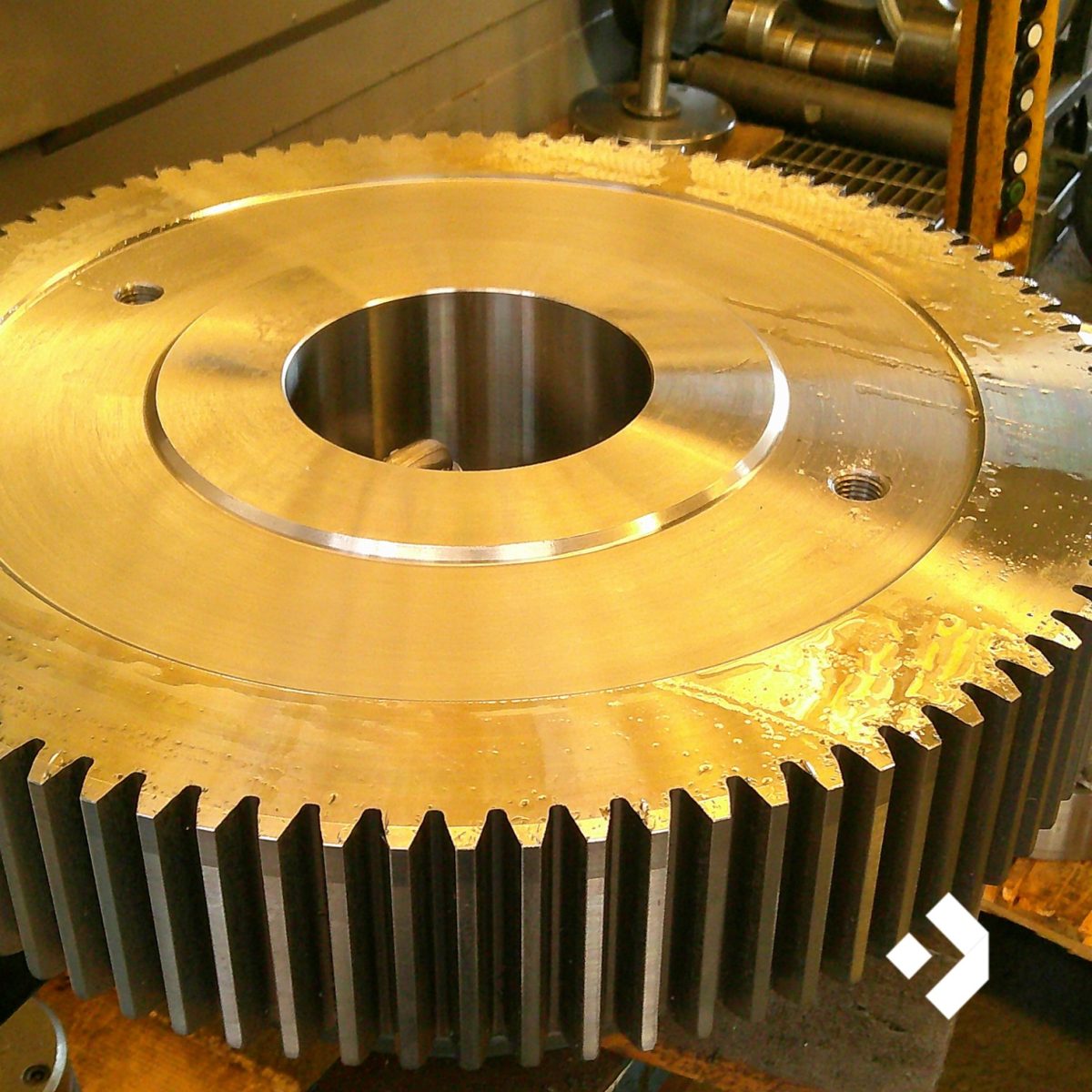

A client in the Mining, Quarrying & Recycling industry required a 2nd reduction spur wheel for a gearbox—an essential component in their heavy-duty machinery. The challenge was to produce a 90-tooth, 6MOD spur gear that would be suitable for case hardening and subsequent gear grinding. Given the precision and durability required, the job demanded a high level of technical capability and reliability.

The Solution

LAMOND & MURRAY DEXIS were selected for the project due to their proven track record with the customer, having previously delivered this part to a high standard. The gear was cut using a hob, with the process carefully managed to leave the component safe for gear grinding after heat treatment. The work was carried out using the Churchill PH3612 machine, a versatile piece of equipment capable of cutting not only spur gears but also helical gears and worm wheels, using both hobs and fly tools.

The entire project was completed within a 9-week timeframe, meeting the client’s expectations for both quality and lead time.

The Result

The client was highly satisfied with the outcome, leading to repeat orders for the same part. This case highlights not only the technical capability of Lamond and Murray but also the trust and satisfaction built through consistent delivery and competitive pricing.