Our engineering repair center recently completed a comprehensive refurbishment of a Metso gearbox serving the food the pharmaceutical industry. This sector demands high standards of reliability, hygiene, and performance-making expert gearbox maintenance critical to operational success.

Project Overview

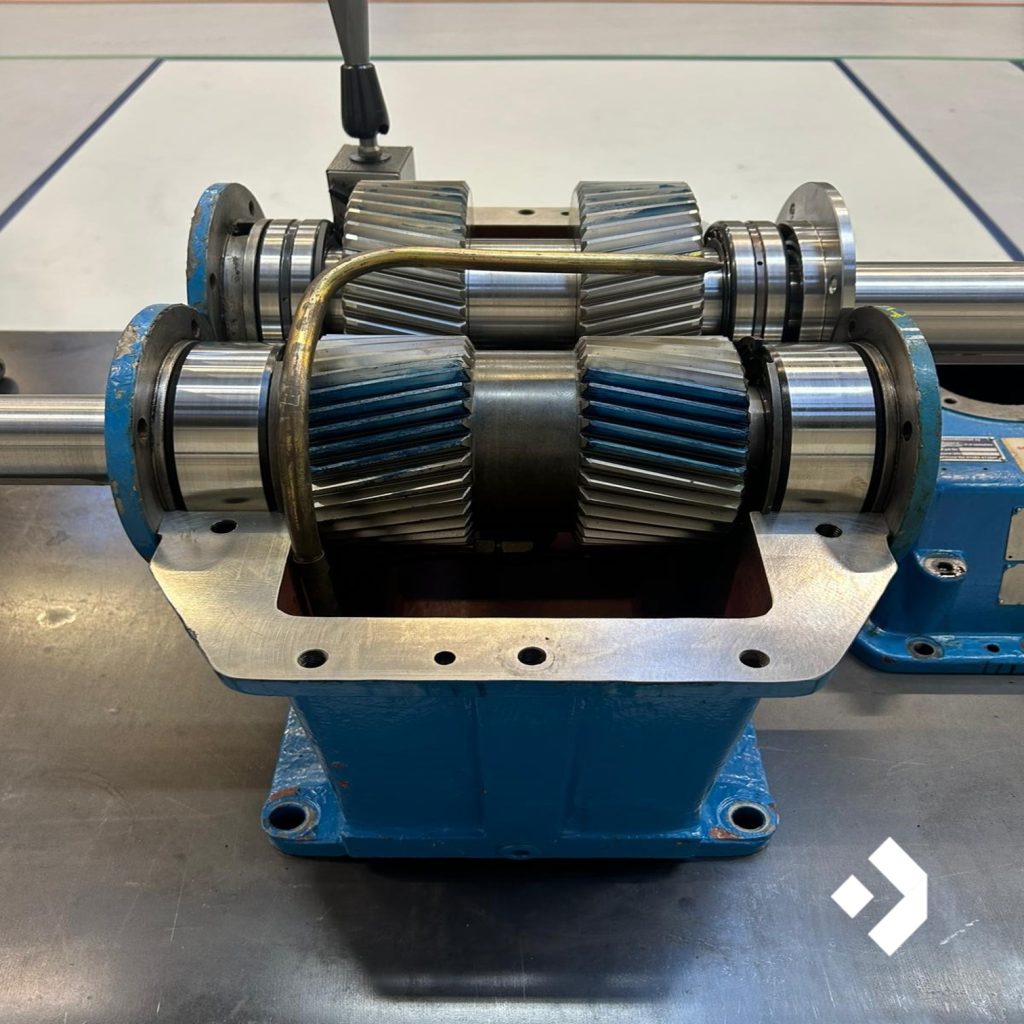

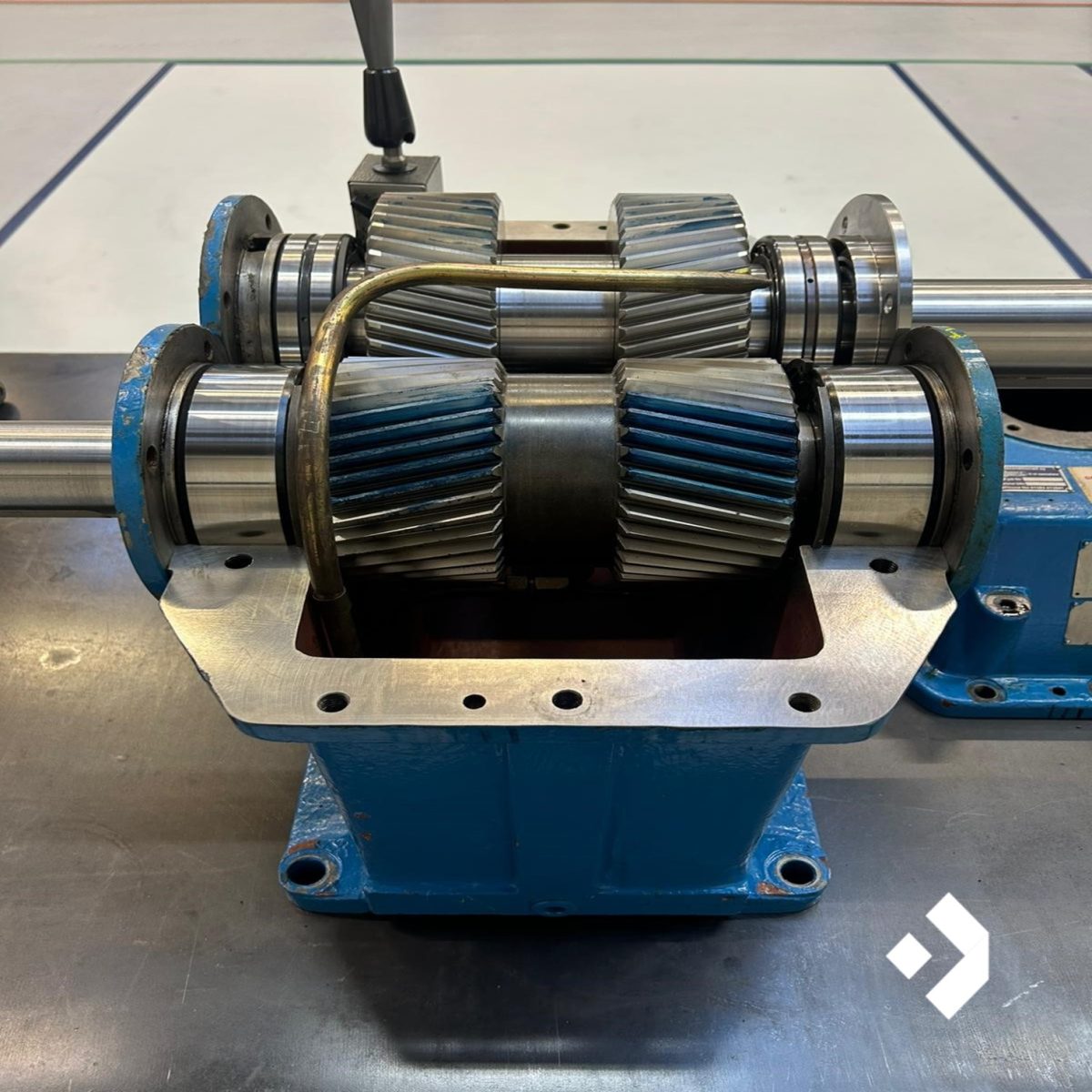

The repair process began with a complete strip-down of the gearbox, followed by thorough cleaning and inspection. A detailed condition report was produced to assess the state of internal components and identify the necessary repair work.

Casing and Gear Repairs:

During inspection, damage was identified in the gearbox casing, which was promptly repaired in-house to restore structural integrity. Several internal gears required replacement due to wear, and new precision-engineered gears were manufactured by Lamond and Murray, specialists in custom gear production.

Component Replacement and Reassembly:

The unit was then fitted with new bearings and seals, all supplied through HAYLEY DEXIS to ensure OEM-grade reliability and performance. Once the necessary components were installed, the gearbox was carefully reassembled by our experience technicians.

Testing and Final Finish:

After reassembly, the gearbox underwent comprehensive testing to verify smooth operation, alignment, and noise levels. Upon successful testing, the unit received a professional paint finish, offering additional protection and a clean, durable appearance ready for return to service.