PROJECT OVERVIEW

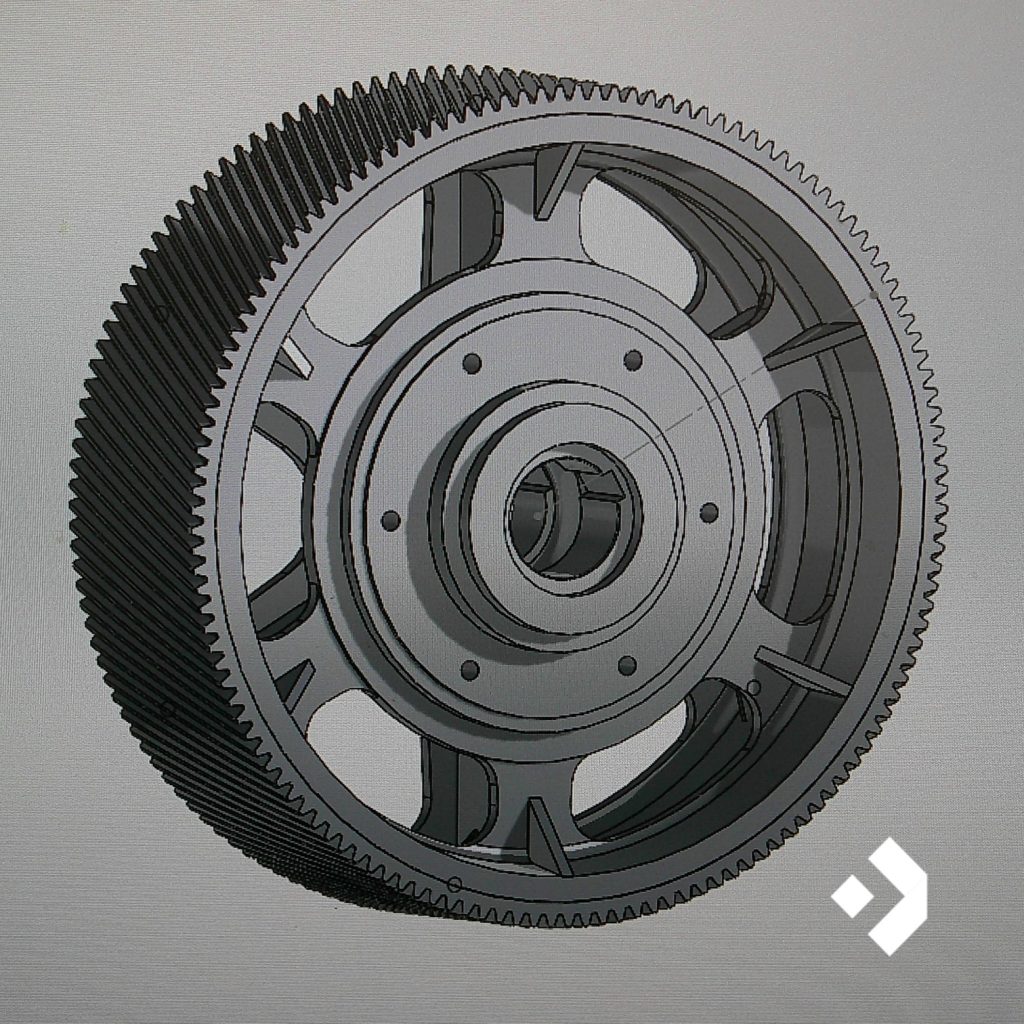

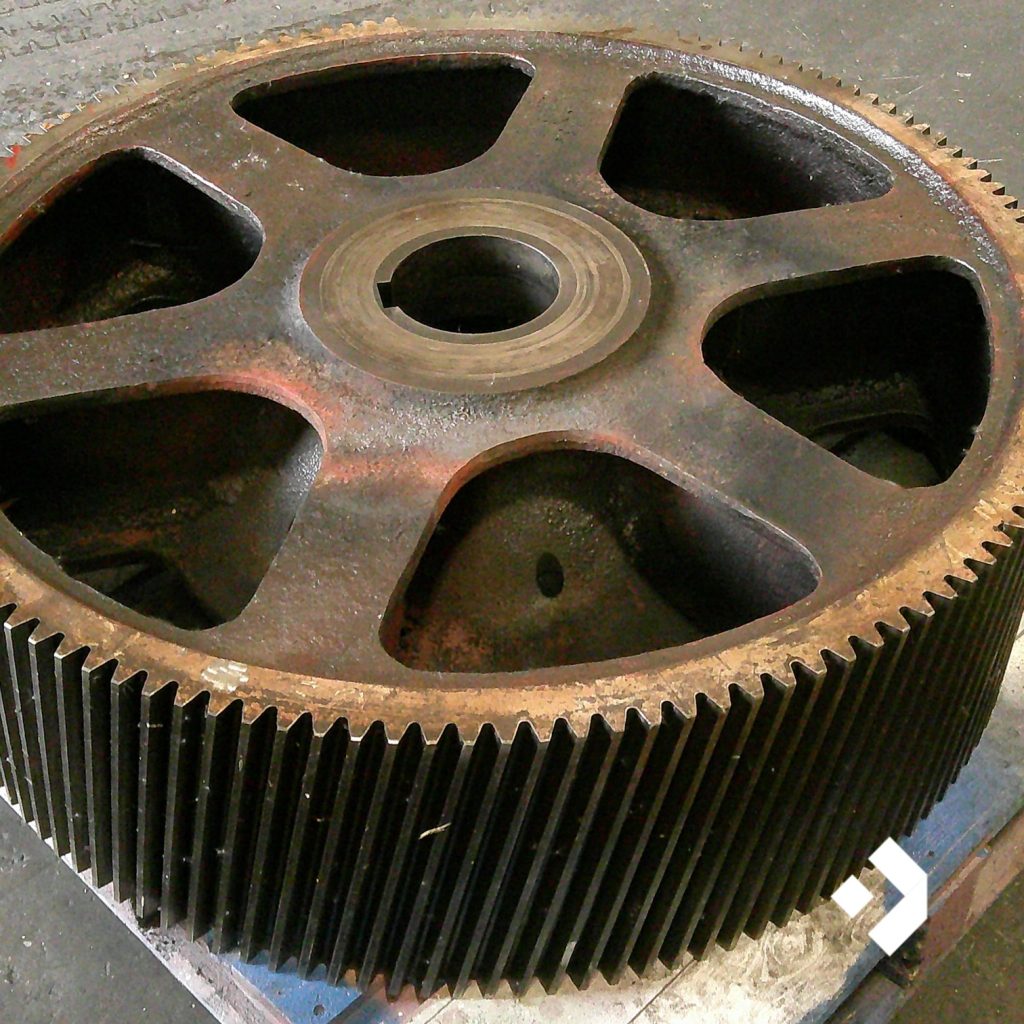

LAMOND & MURRAY DEXIS was commissioned to support a long-standing client in the fluid engineering and chemical processing industry. The task: reverse engineer and manufacture a helical gear assembly within an 11-week lead time. The project involved transforming a worn, damaged sample into a fully functioning, precisely assembled part ready for industrial use.

THE PROBLEM

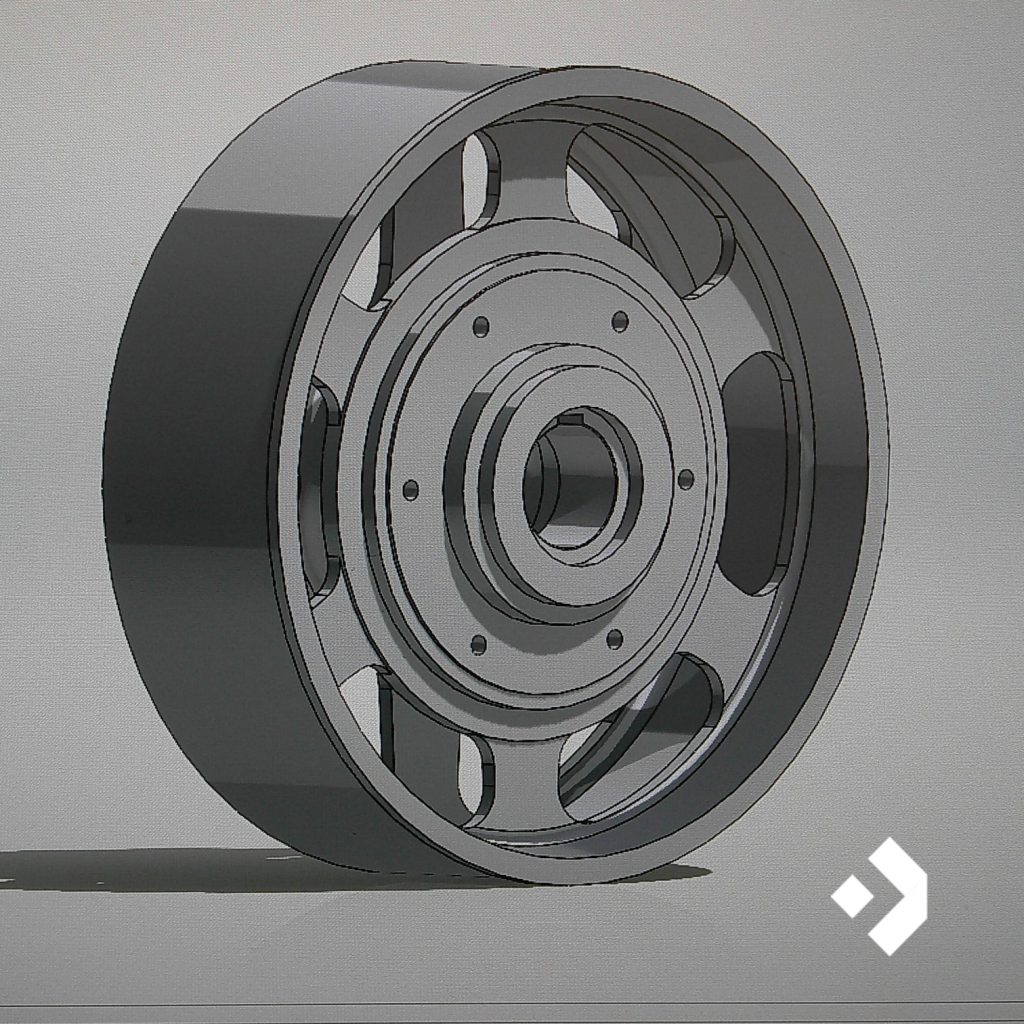

The client needed a replacement helical gear assembly, but the original component was significantly worn—and no technical drawings were available. Additionally, the gear rim required a modular approach to allow future replacement without discarding the entire cast centre. This demanded a creative, high-precision solution that would extend component lifespan while meeting strict performance requirements.

THE SOLUTION

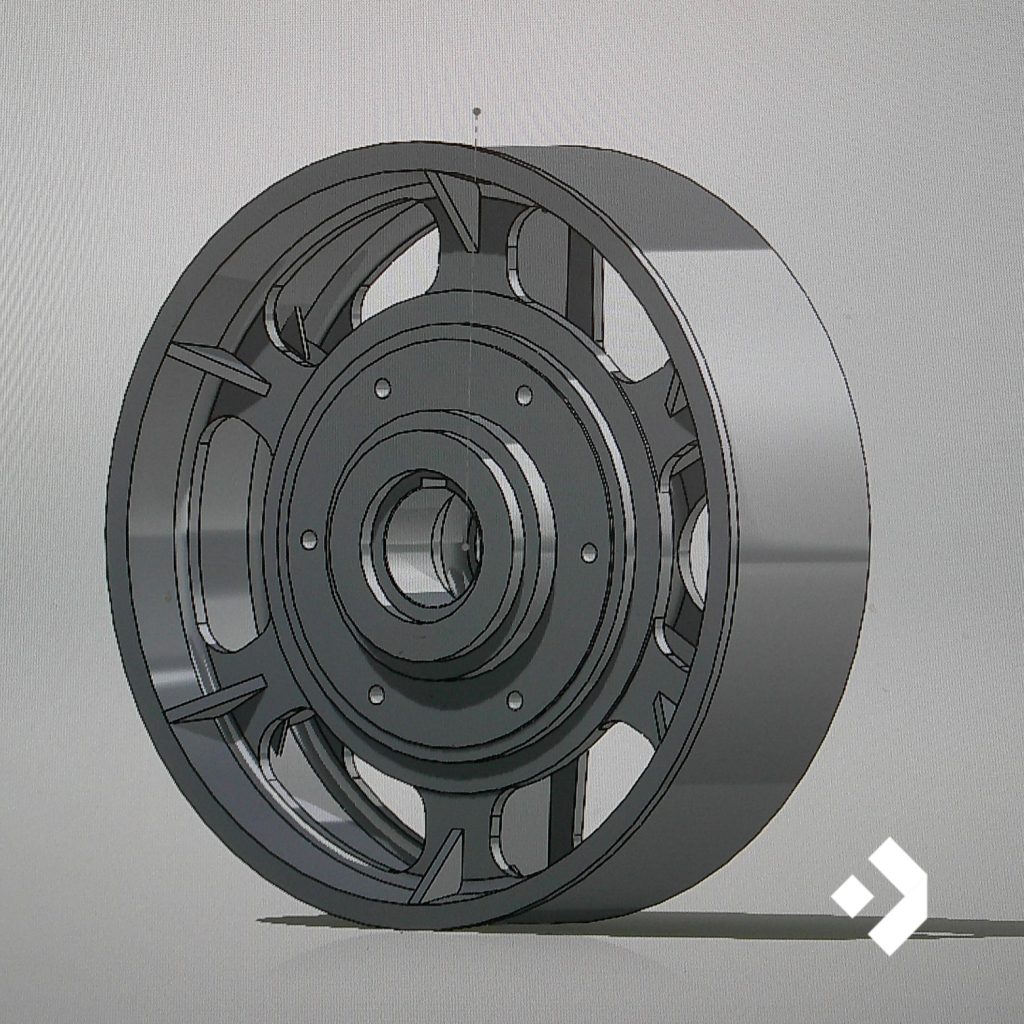

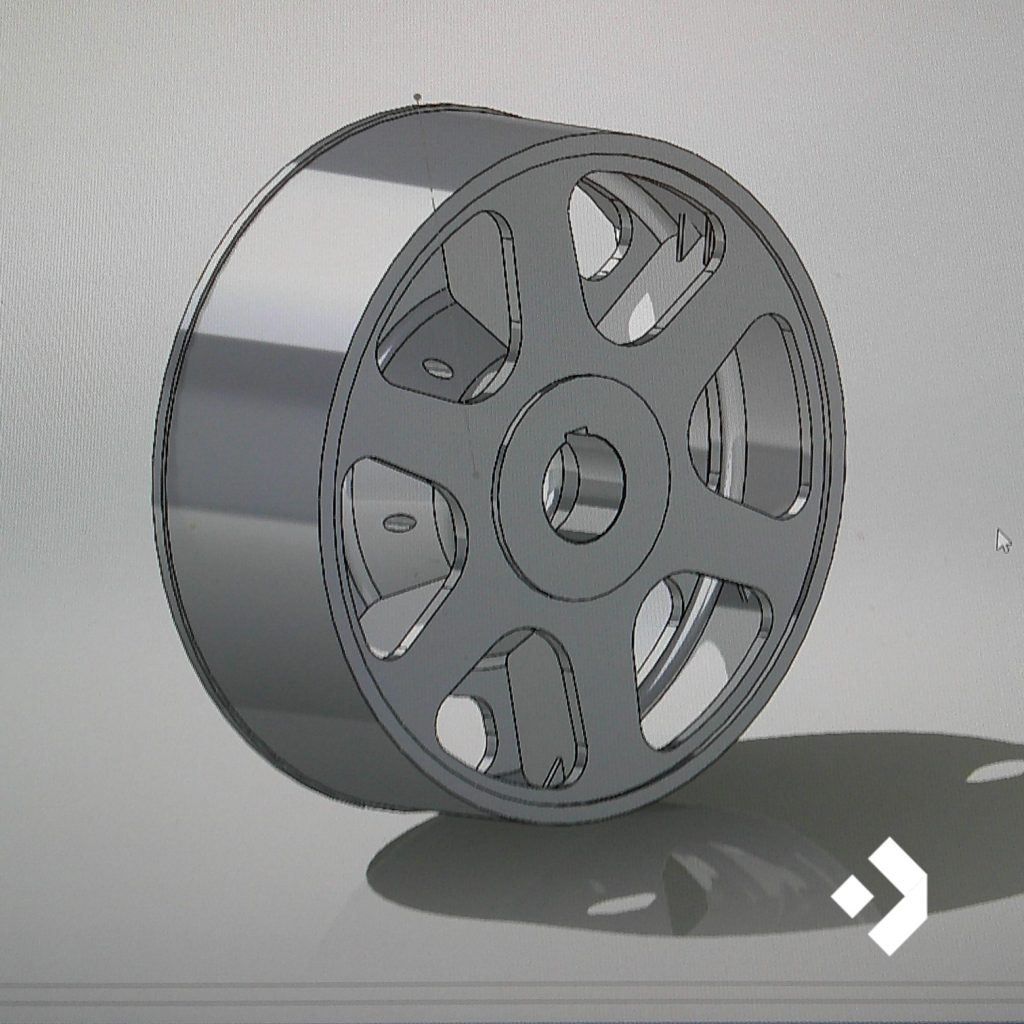

LAMOND & MURRAY DEXIS’ engineering team began by reverse engineering the worn sample. The process included:

– Turning the rim and cast centre separately

– Assembling the aligning both parts

– Drilling and tapping to secure the rim and centre

– Gear cutting the rim on the casting to restore the original tooth profile

This modular design provided a sacrificial gear-cut rim, allowing the client to replace only the worn section in future, reducing downtime and cost.

THE RESULT

The completed assembly met all client expectations and was delivered within the agreed timeframe. This innovative solution not only restored functionality but also introduced a longer-term maintenance advantage. The client has since placed repeat orders for similar components, reinforcing their trust in LAMOND & MURRAY DEXIS’ quality, pricing, and lead time.