Project Overview

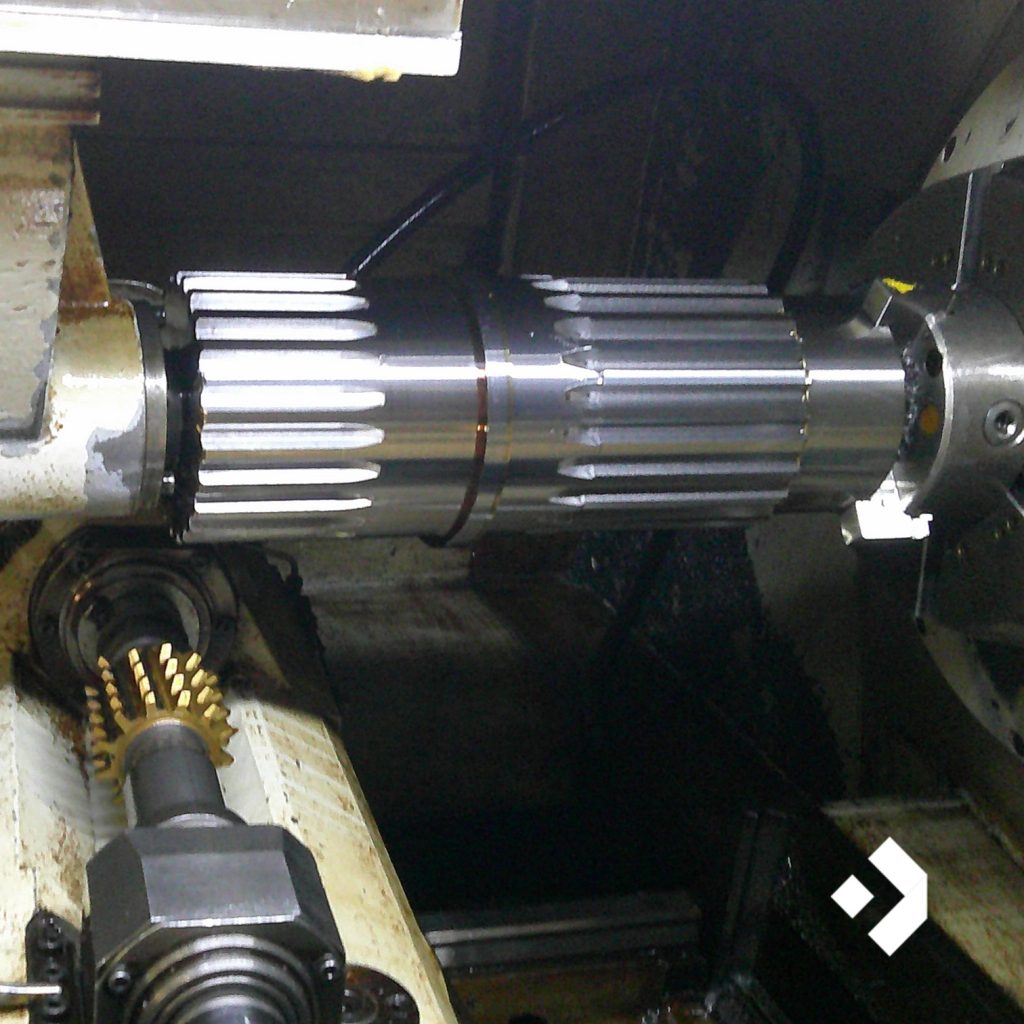

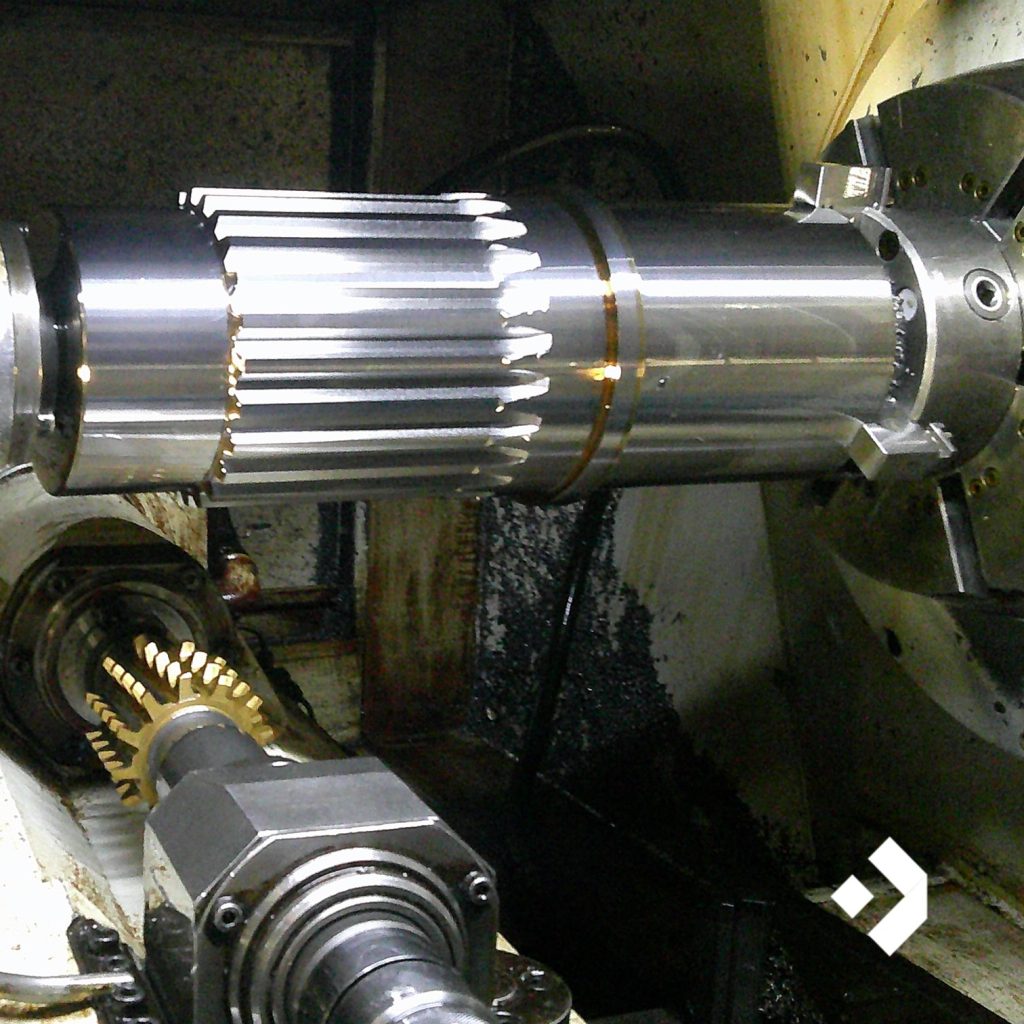

LAMOND & MURRAY DEXIS was recently selected by a customer in the mining industry to manufacture a double-splined output shaft for a gearbox – essential part of their heavy-duty drive system. With a tight 8-week turnaround, the client required precision engineering to ensure optimal performance in a demanding environment.

The Problem

The project called for a 24-tooth 4/8DP 30-degree spline to be machined at both ends of the shaft, sized accurately using pins to the customer’s specification. Given the complexity of the part and the need for exact tolerances, the client needed a trusted engineering partner capable of delivering both high-precision turning and reliable spline cutting without delay.

The Solution

The LAMOND & MURRAY DEXIS team handled the entire process in-house. Using our P3100XLY machine, the shaft was turned and drilled to specification. We then gear-cut the splines using our Gleason P320 CNC gear cutting machine, ensuring full spline length with minimal overtravel. This approach not only preserved the adjacent diameters but also met all functional and dimensional requirements. Our ability to perform both turning and drilling on a single machine, combined with accurate CNC spline cutting using hobs, reduced lead time and maximised productions efficiency – key factors in this project’s success.

The Result

The project was completed on time and to spec, earning praise from the customer for both quality and value. As a result, the client placed repeat orders for the same component, reinforcing their trust in our consistent delivery and engineering capabilities.