The Problem

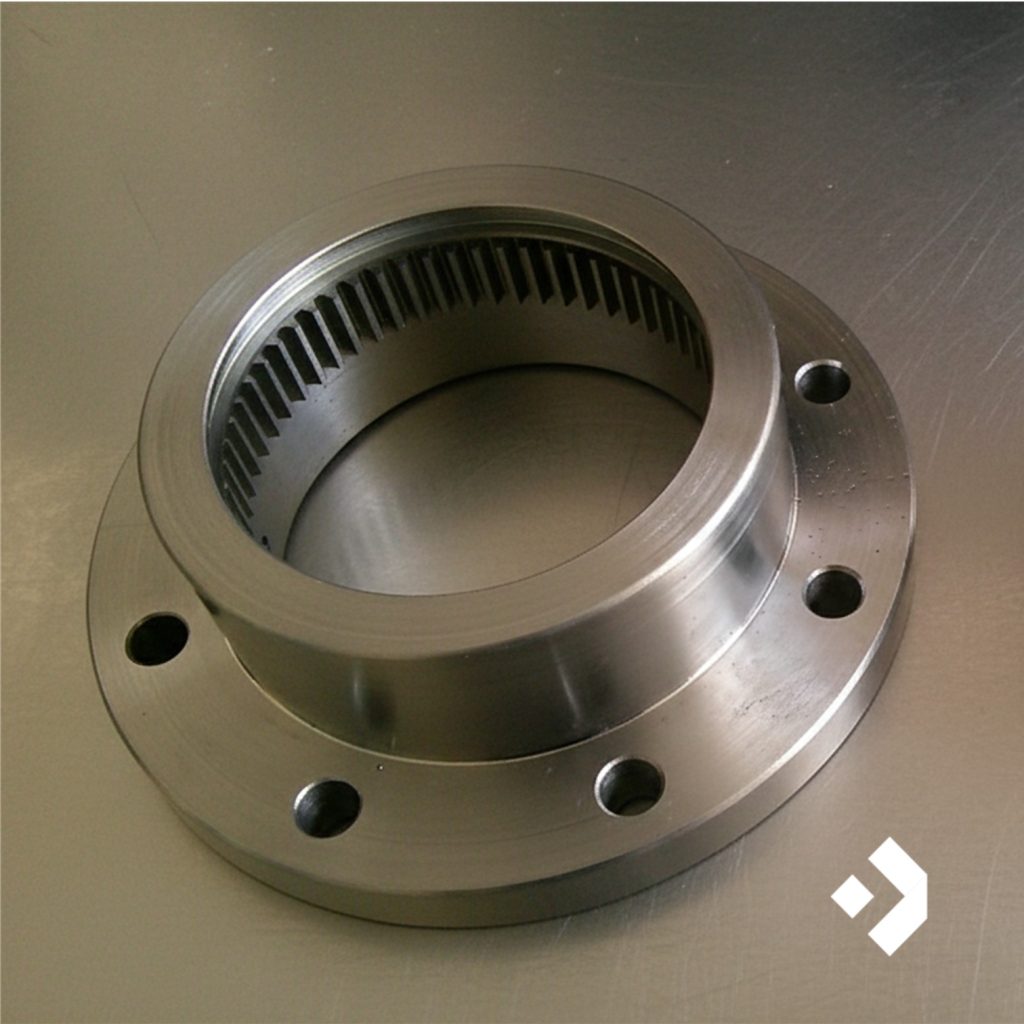

A client in the steel industry needed to replace input half coupling hubs and flanged parts for a Benzler gearbox. The original components were damaged and no technical drawings were available, making the job dependent on reverse engineering from the sample part. The challenge was to deliver a precise, functional replacement within a 7-week timeframe.

The Solution

LAMOND & MURRAY DEXIS were chosen due to their proven track record with the customer, who had previously sent in multiple gearboxes for refurbishment. The team reverse-engineered the damaged part and carried out a series of operations:

– Finish turning on the Harrison 390 manual lathe

– Drilling and tapping using the PCD drill

– Internal spline gear cutting using the V400 Sykes gear shaper

This project showcased the versatility of LAMOND & MURRAY DEXIS’ workshop, where multiple machines were used in tandem to recreate a critical gearbox component from scratch.

The Result

The customer was once again impressed by the quality, lead time, and pricing, leading to repeat orders for gearbox refurbishment. This case highlights LAMOND & MURRAY DEXIS’ ability to deliver complex, multi-process engineering solutions even when starting from incomplete or damaged samples.