Project Overview

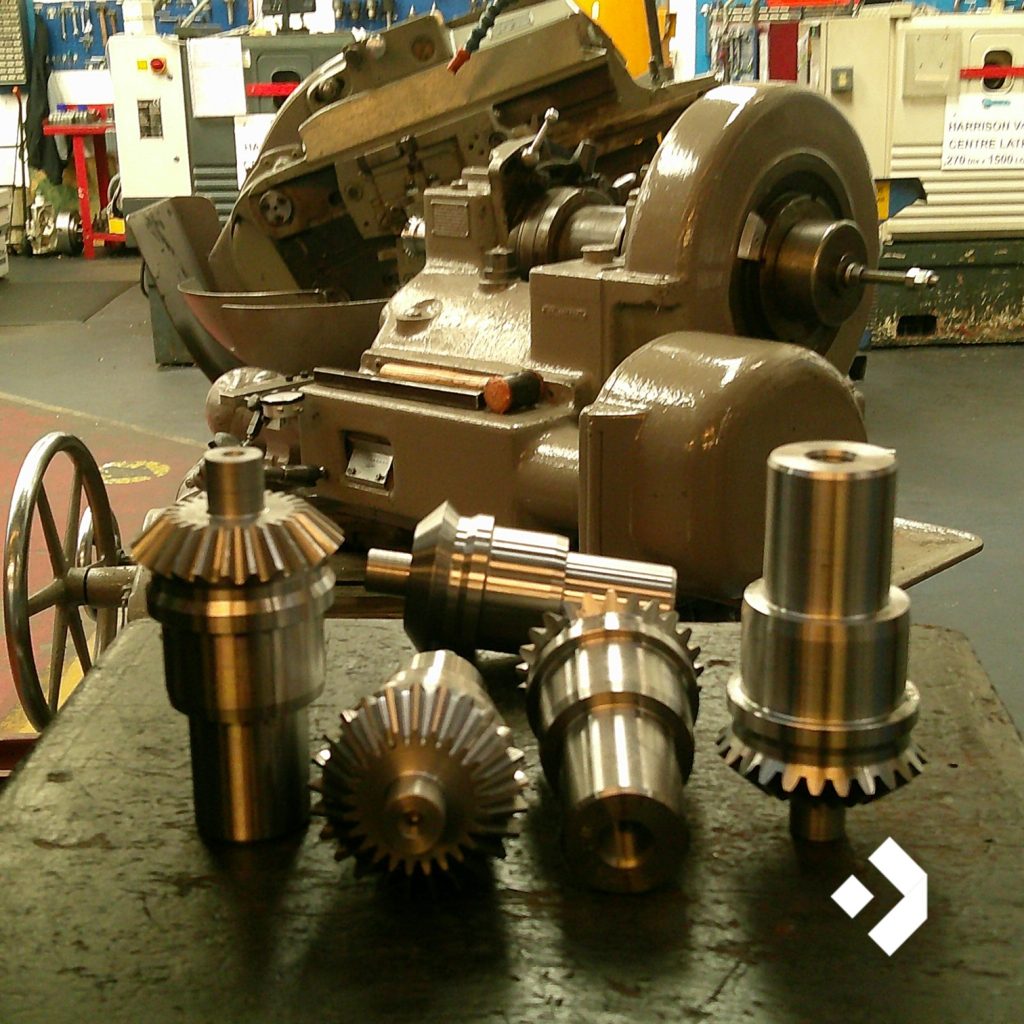

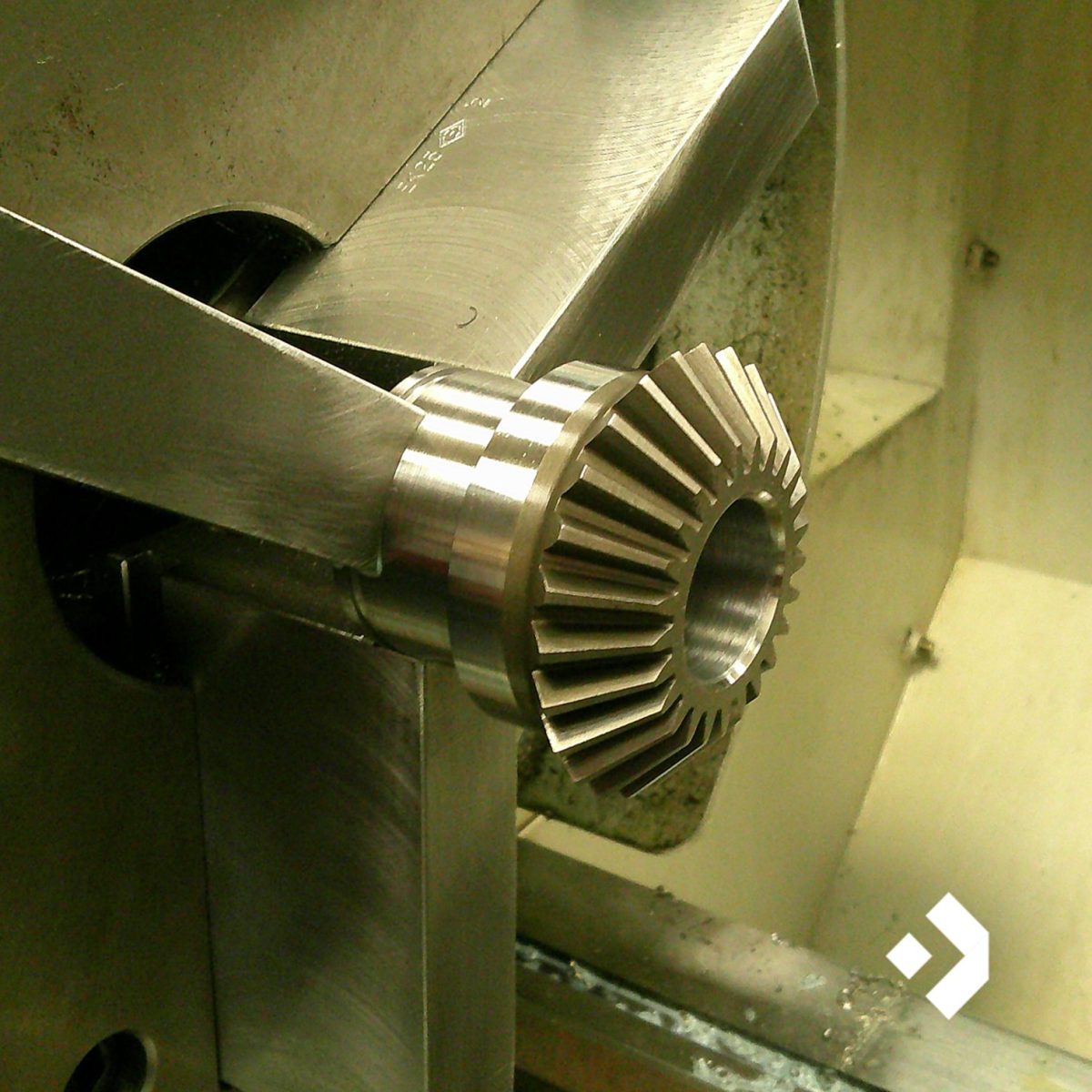

LAMOND & MURRAY DEXIS was recently entrusted with the production of a custom bevel gear used in a hot tap drilling machine – a critical tool in the global energy sector. With a project timeline of 11 weeks, the customer required a high-performance gear built to exacting specifications.

The Problem

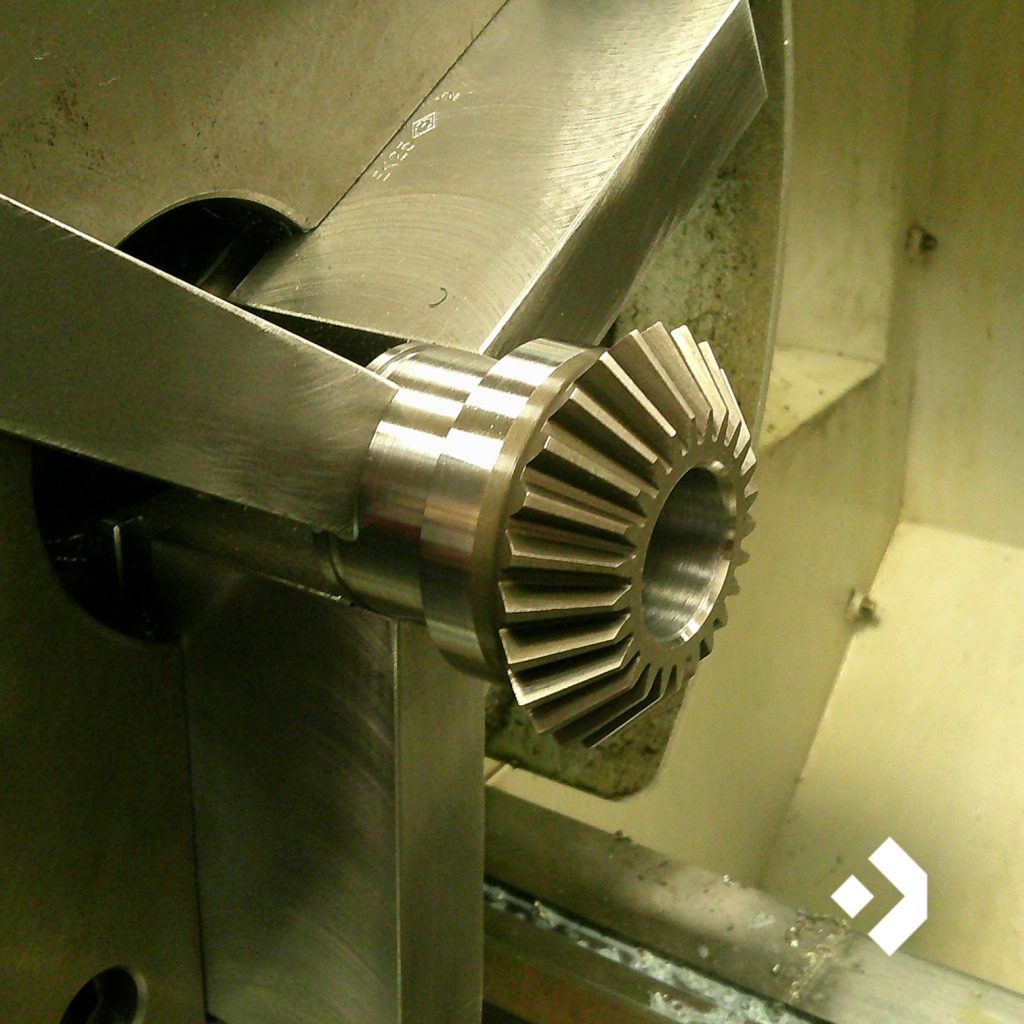

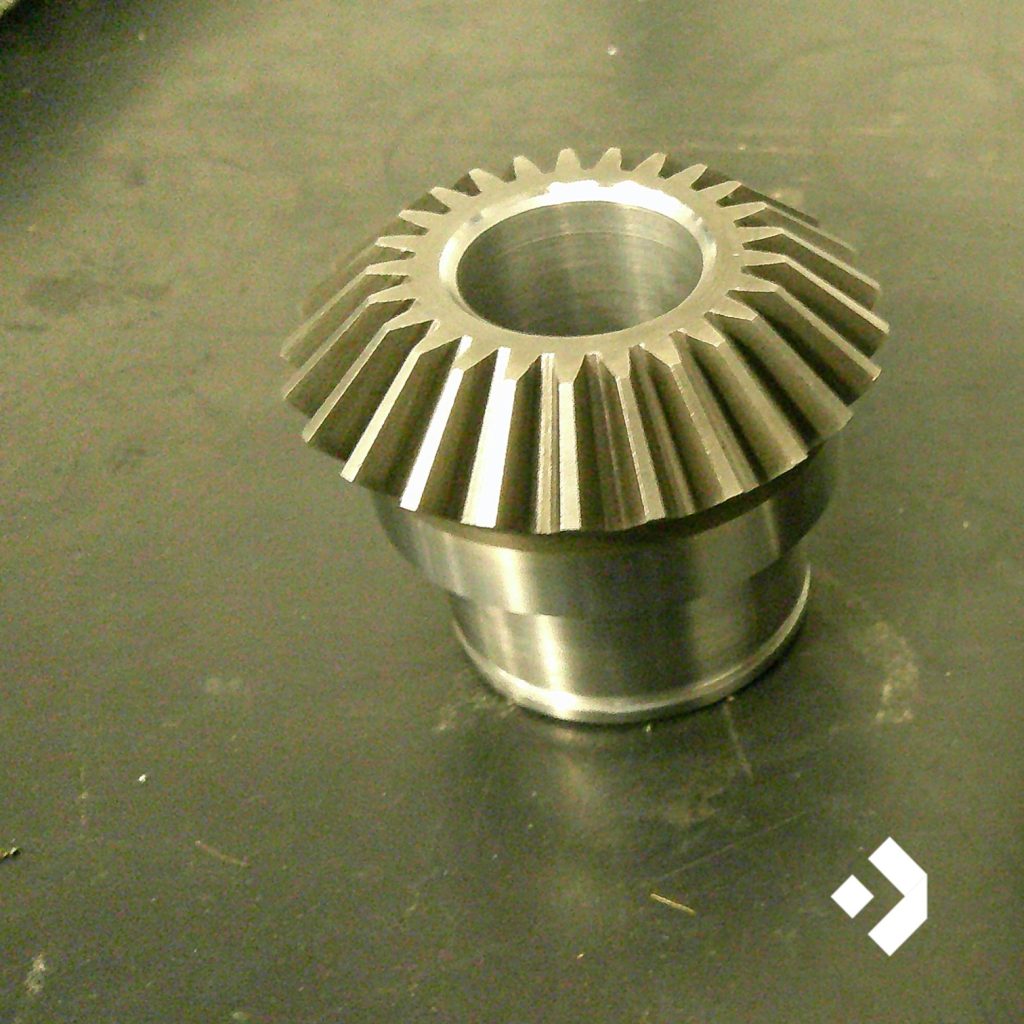

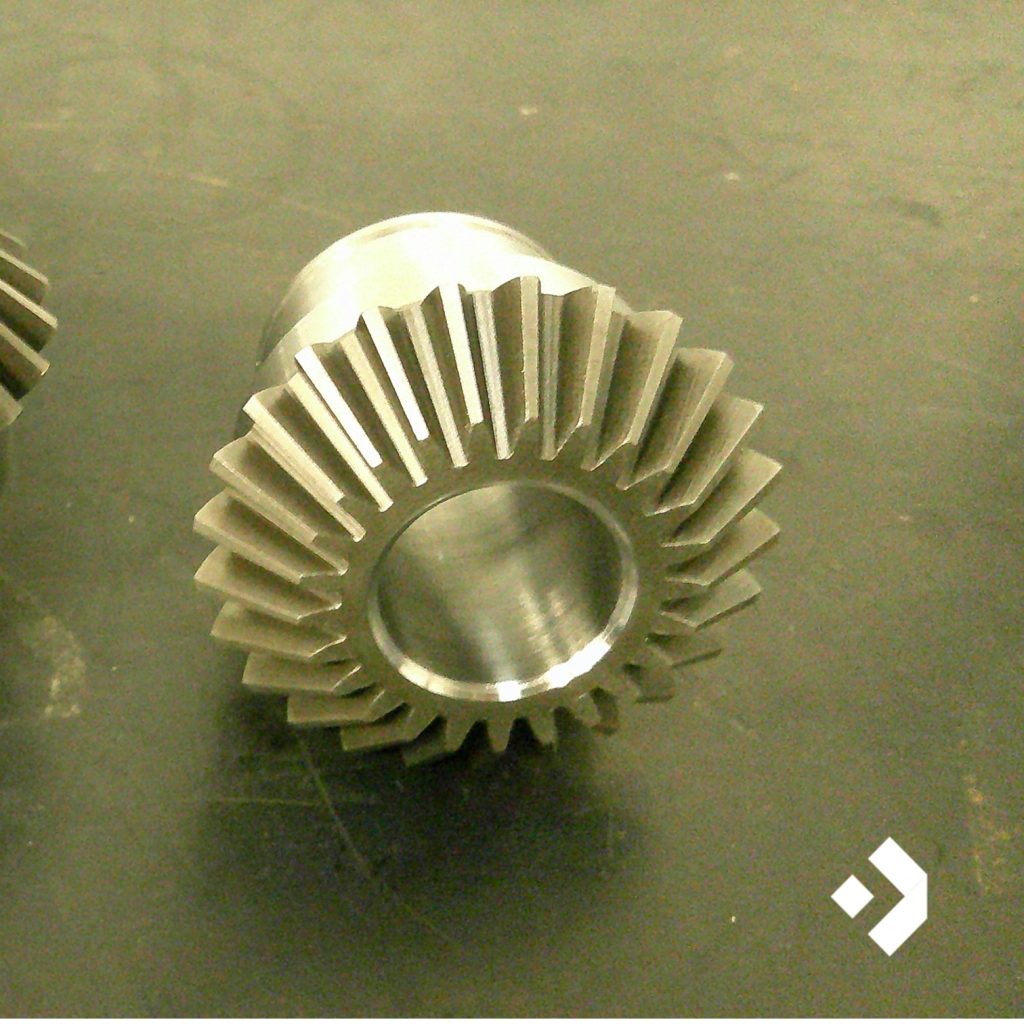

The client needed a 25-tooth, 2.5MOD straight-tooth bevel gear, manufactured to tight tolerances and case-hardened for durability. As a repeat job with no room for error, precision and reliability were essential to ensure optimal performance during high-pressure drilling operations.

The Solution

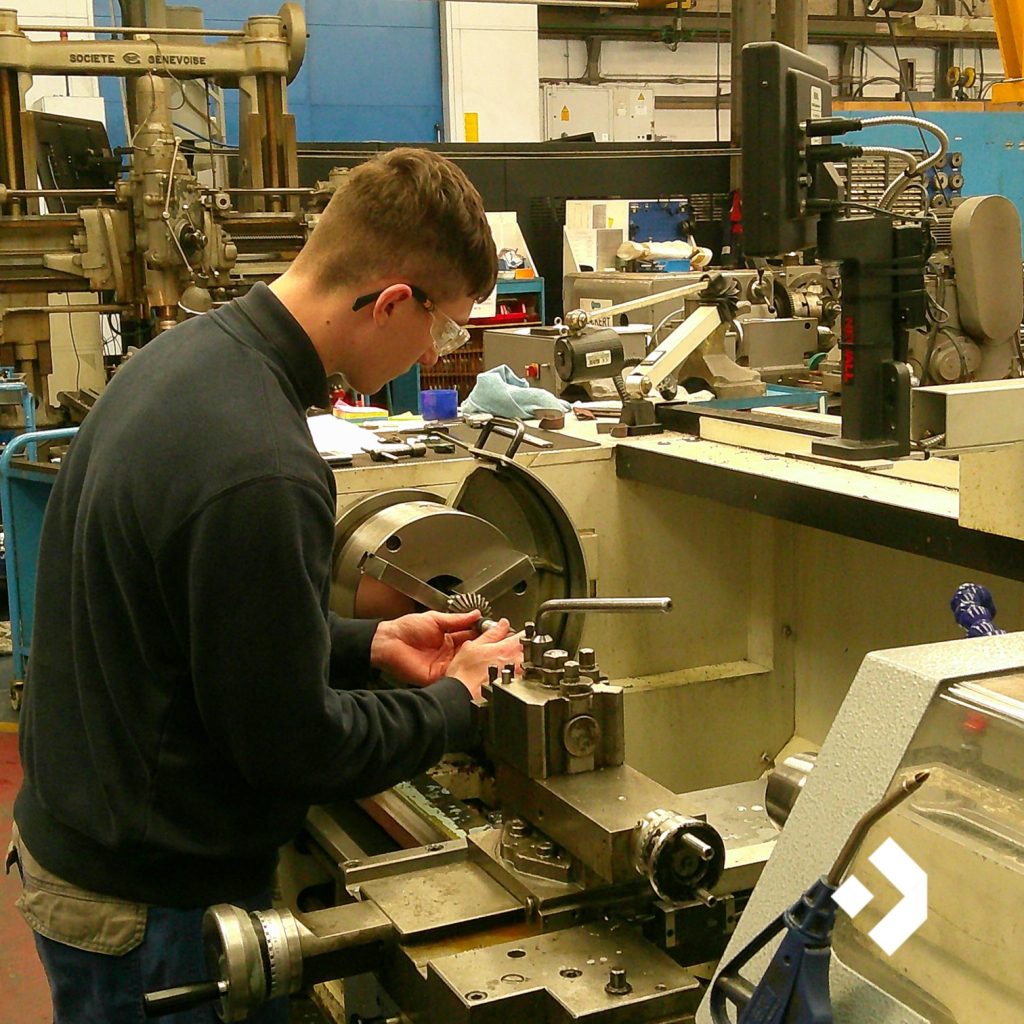

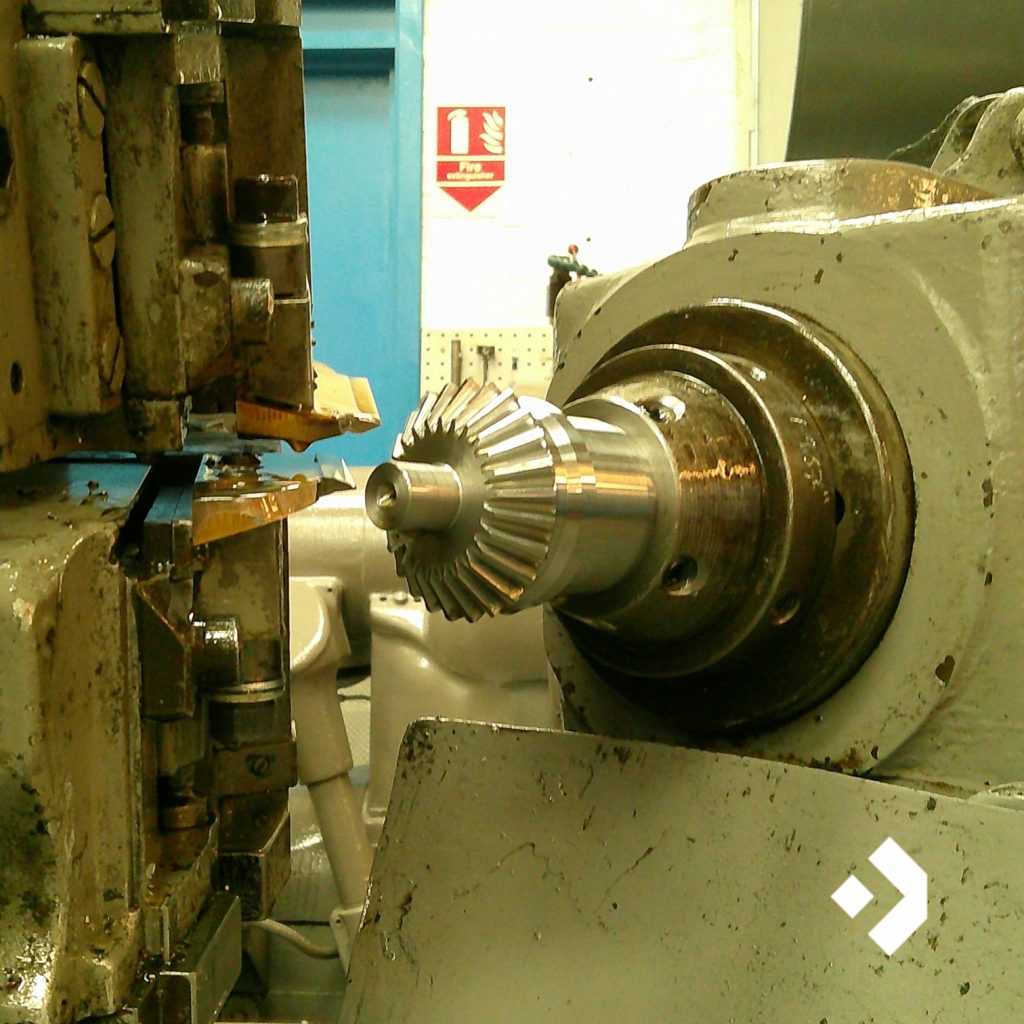

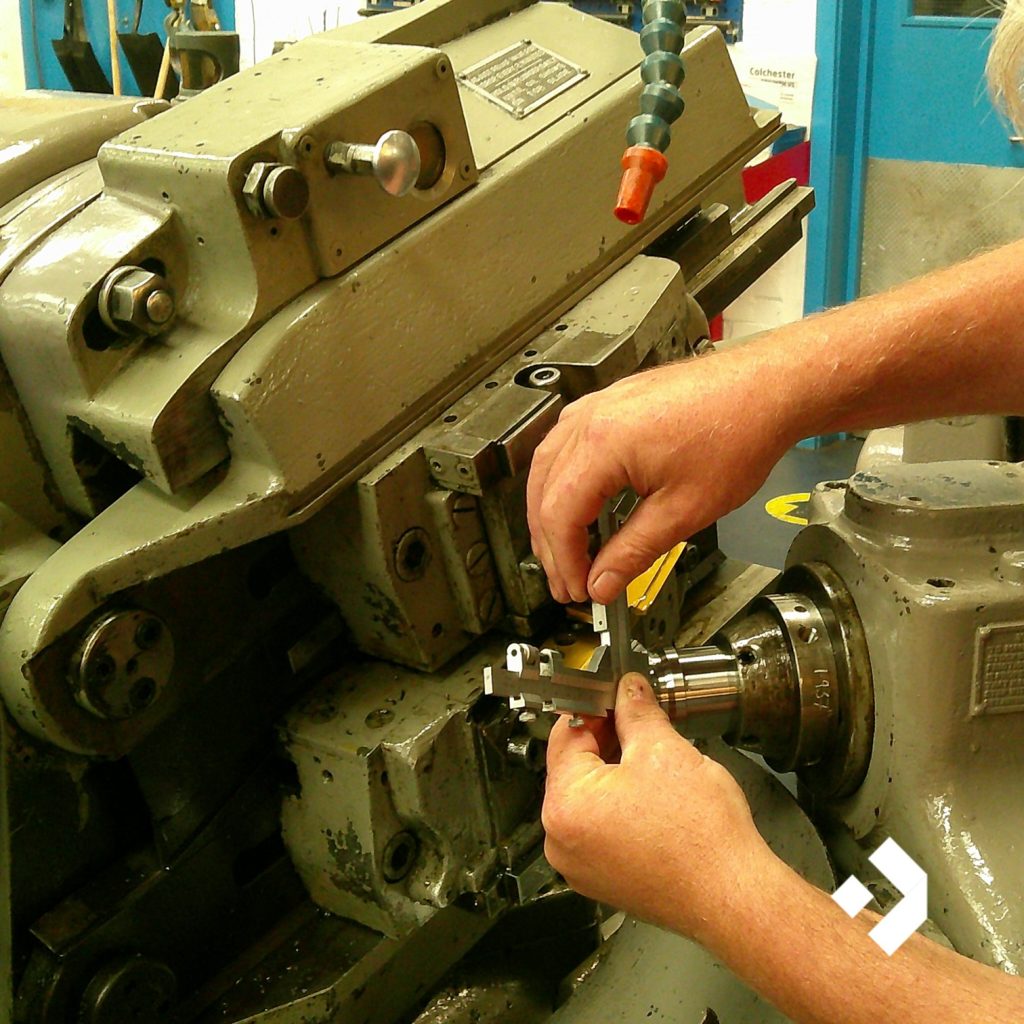

Our skilled engineering team utilised the No.12 Gleason bevel gear generator to accurately gear-cut the bevel profile. Once cut, the gear underwent case hardening to increase wear resistance and was finish-turned to match all required customer specifications.

This project showcased LAMOND & MURRAY DEXIS’ ability to handle complex bevel gear production from start to finish, delivering a fully machined, hardened component with zero compromise on quality.

The Result

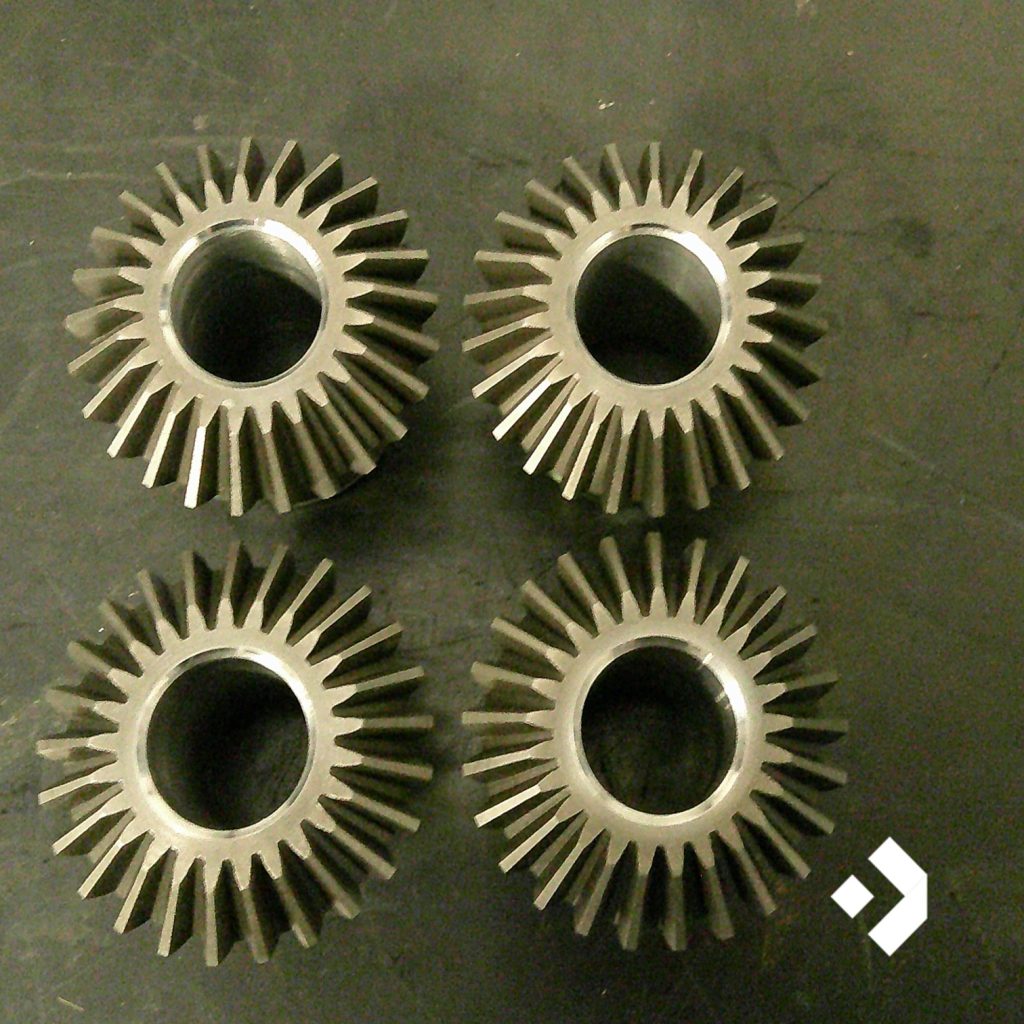

The gear was completed and delivered on time, fully compliant with the customer’s dimensional and material standards. As a result, we secured repeat orders from the client – reinforcing their confidence in our consistent workmanship, competitive pricing, and lead time.