Industry: Construction / Manufacturing

Lead Time: 4 Weeks

Component: Double Helical Pinion

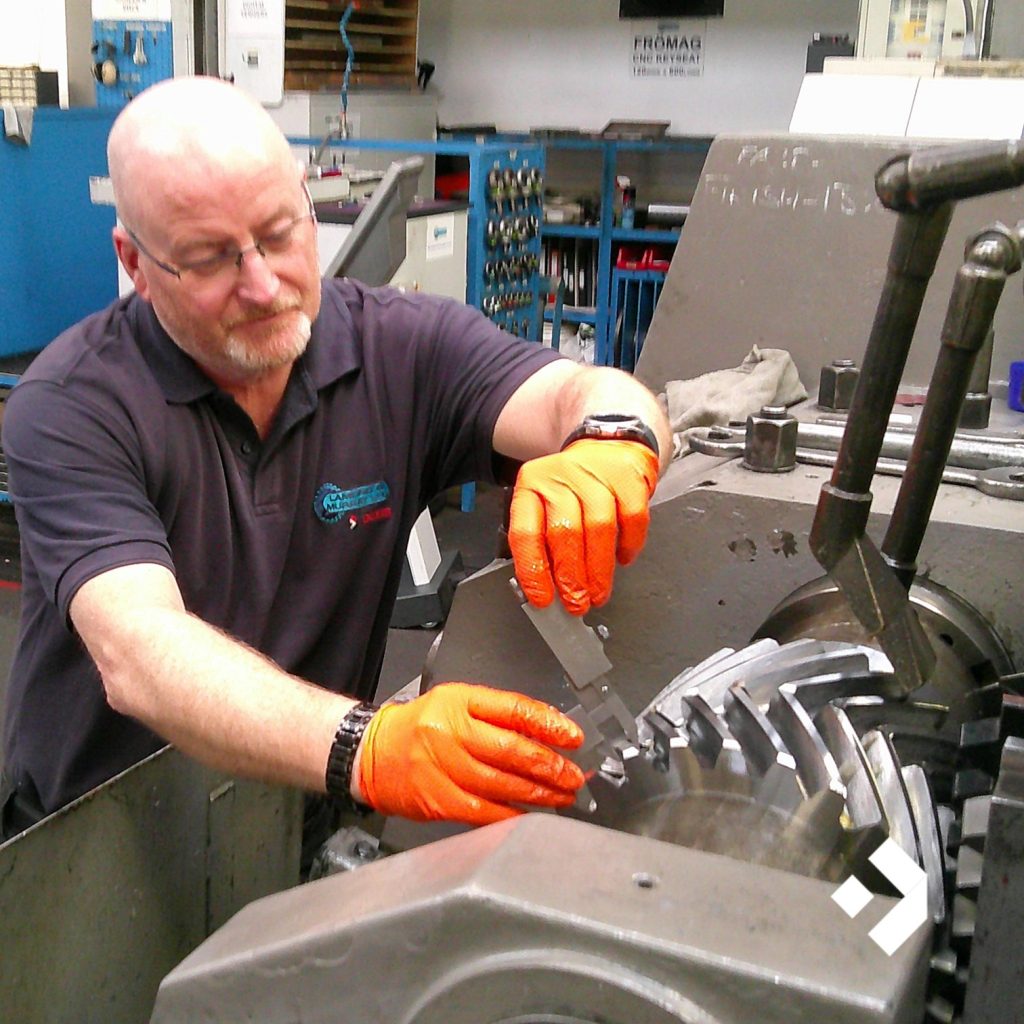

Lamond & Murray was recently selected to support a new customer in the construction materials sector with the manufacture of a precision double helical pinion. The component plays a key role in machinery used to produce mineral fibre acoustic ceiling solutions—a critical product widely used in commercial and industrial buildings.

Project Overview

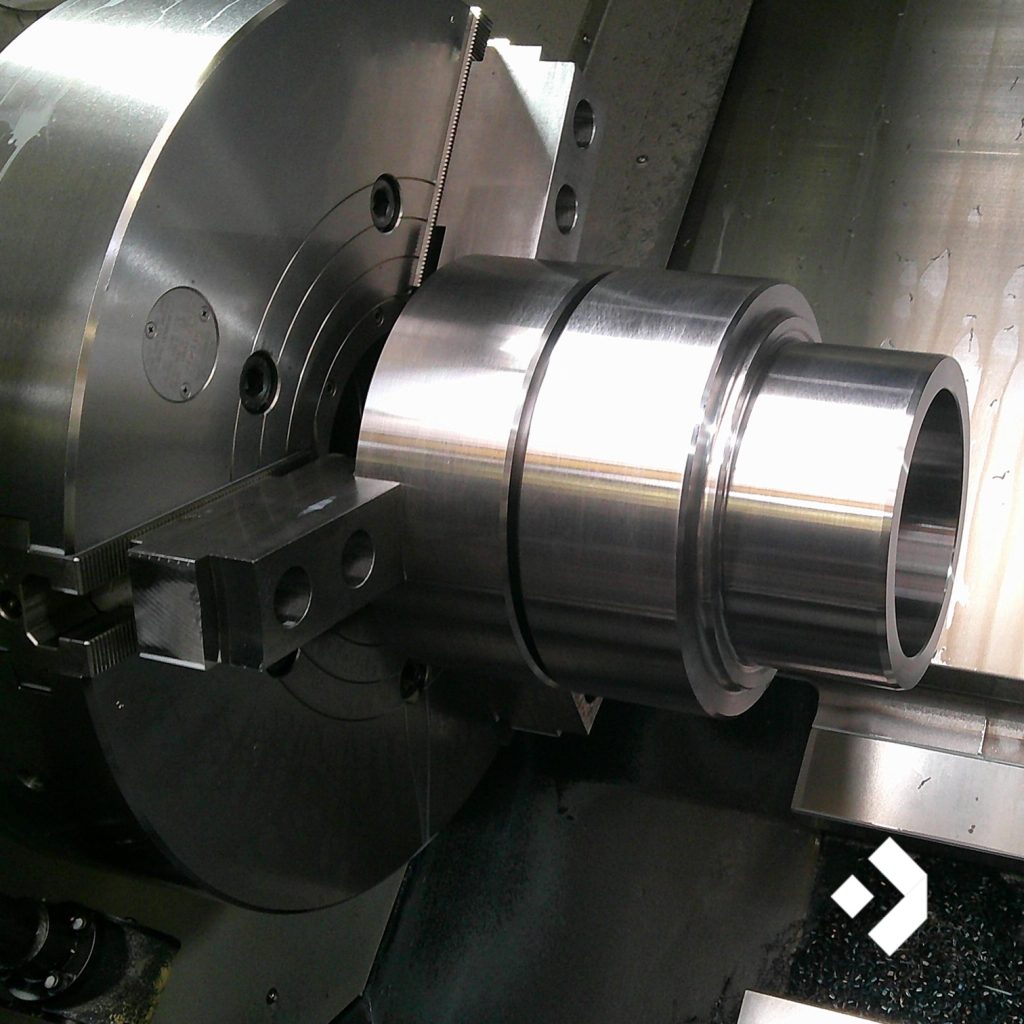

The customer approached LAMOND & MURRAY DEXIS with a request to manufacture a double helical pinion to exact specifications outlined in their engineering drawings. The job required a tight manufacturing tolerance, high surface finish, and close attention to gear tooth alignment. Our engineering team carried out the gear cutting process using the Sunderland G150 gear cutting machine, a reliable platform for handling double helical forms.

What Made This Project Unique

This job showcased our capability to gear cut double helical pinions with minimal gap between the opposing helix angles – a technical challenge requiring both experience and highly accurate tooling. Maintaining strict tolerances was essential to meet the functional demands of the machinery and the customer’s expectations.

Why Choose LAMOND & MURRAY DEXIS

This was the client’s first time working with LAMOND & MURRAY DEXIS, and their decision was based on several key factors:

- Our ability to deliver to exact customer drawings and technical specifications

- Attractive pricing and lead time compared to alternative suppliers

- Confidence in our gear cutting capabilities and in-house inspection standards

HEY HIGHLIGHTS

- High-precision double helical pinion delivered on time

- Full compliance with dimensional tolerances and specifications

- New customer relationship established – with potential for future collaboration