PROJECT OVERVIEW

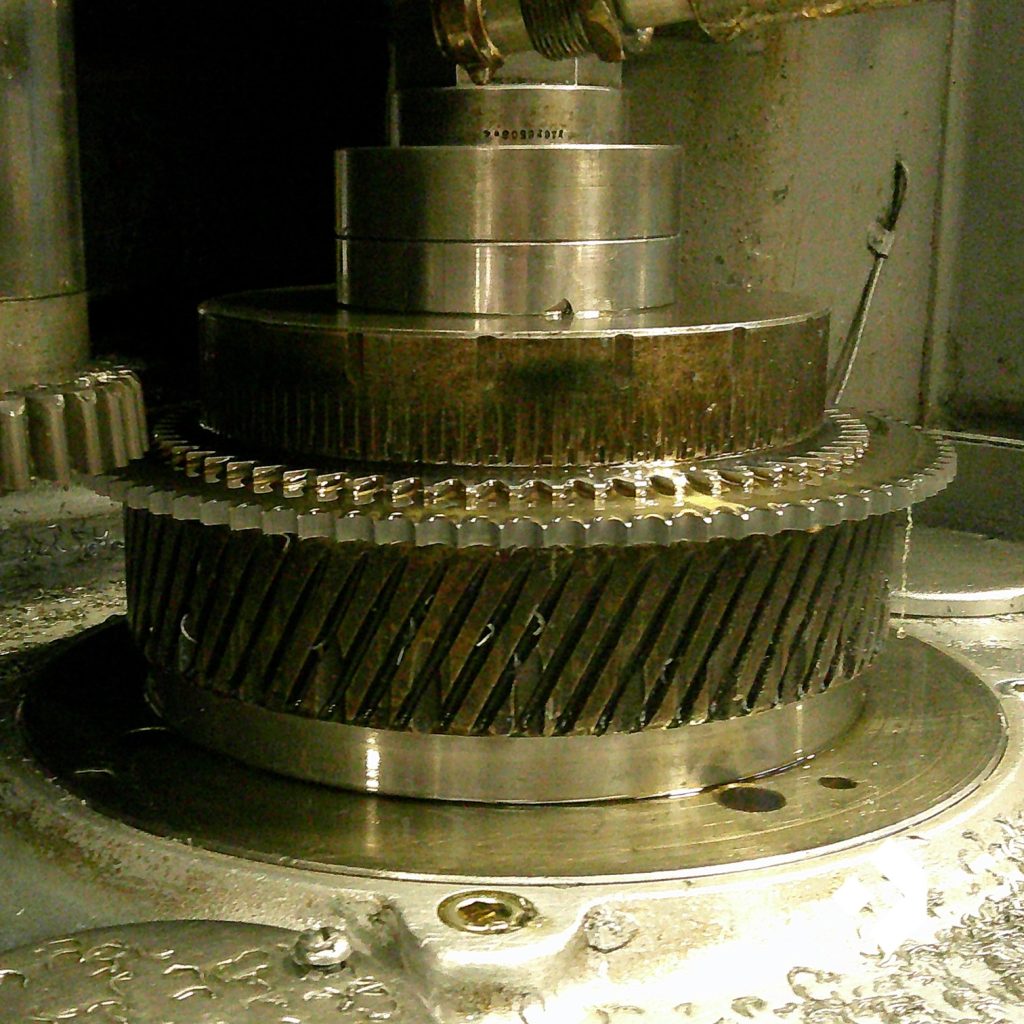

LAMOND & MURRAY DEXIS was recently commissioned to manufacture a precision-engineered sprocket for a hot tap drilling machine – an essential tool in the global energy sector. With a tight 4-week turnaround, the project required expert machining and gear cutting to ensure the final part met demanding performance standards.

The Problem

The customer needed an 84-tooth, 3/8″ pitch sprocket, manufactured precisely to drawing specifications. This component plays a crucial role in the operation of hot tap drilling machines, where reliability and precision are non-negotiable. With no margin for error and a tight lead time, the client turned to LAMOND & MURRAY DEXIS for a high-quality, dependable solution.

The Solution

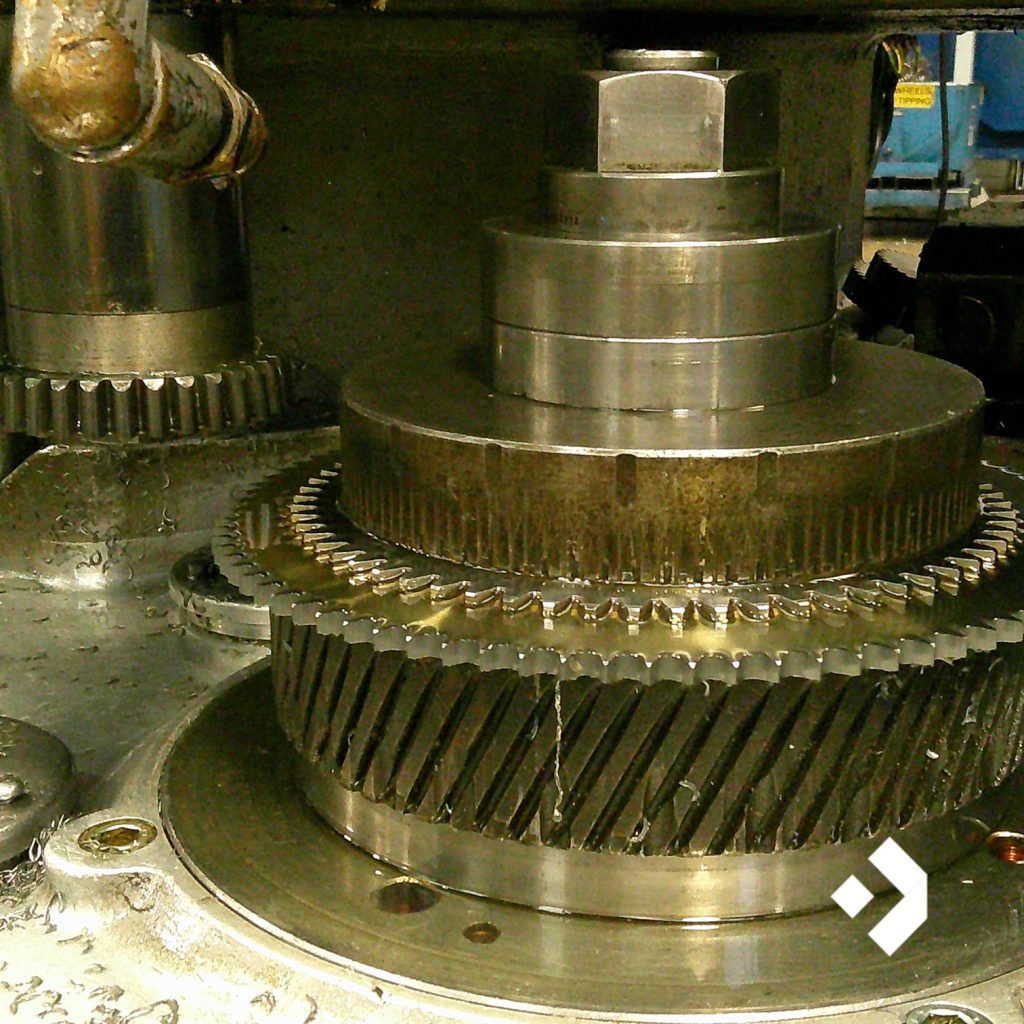

Our team employed a multi-step, in-house machining process:

– Manual turning on our Harrison V460 lathe

– Drilling to spec using our PCD drill

– Gear cutting the 84T sprocket teeth with our Fellows gear cutting machine

This combination of manual craftsmanship and precision machinery allowed us to deliver a fully compliant component that matched the customer’s exact requirements.

What Made It Stand Out

The versatility of our workshop setup was key. We were able to turn, drill and gear cut the sprocket using multiple machines, all under one roof. This streamlined workflow minimised delays, reduced handling, and ensured complete control over quality and turnaround.

The Result

The sprocket was delivered on time and to full specification, earning us repeat orders from the customer. Once again, attractive pricing, fast lead times, and quality workmanship made LAMOND & MURRAY DEXIS the partner of choice.