Project Problem

A long-standing client in the mining and quarrying industry approached LAMOND & MURRAY DEXIS with a critical need: a custom-engineered gear for a mineral sizer gearbox. The gear had to meet exacting specifications and withstand the harsh conditions typical of mineral processing environments. With a tight turnaround of just 11 weeks, the challenge was not only technical but also logistical – requiring precision, speed, and reliability.

The Solution

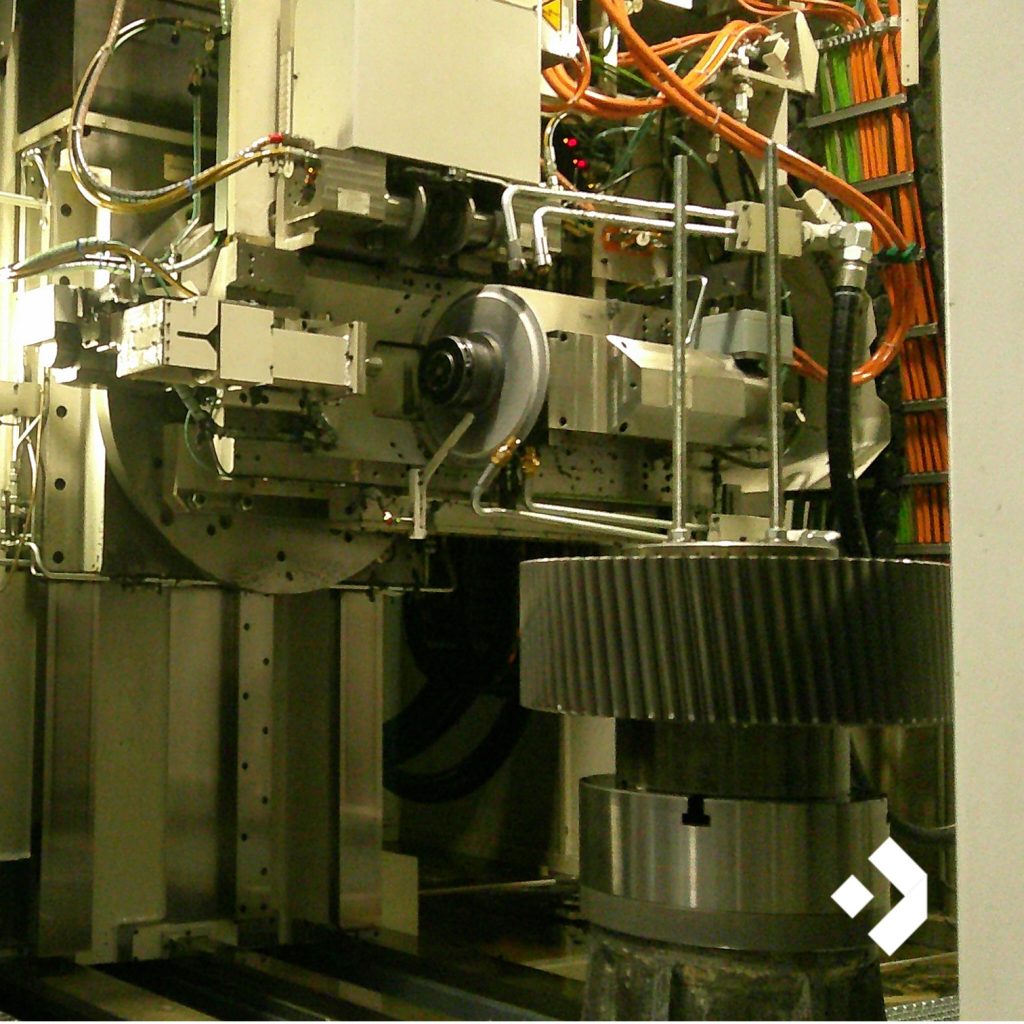

LAMOND & MURRAY DEXIS took on the project with confidence, drawing on their extensive experience and reputation for quality. The process began with a full engineering setup and a comprehensive inspection before any machining took place. Once the groundwork was complete, the gear teeth were ground using the P1480G machine, followed by a separate inspection to verify the span size post-grinding.

The gear itself was manufactured to the customer’s drawing and specification. It featured 73 teeth, an 8 module, a 20-degree pressure angle, and a left-hand helical profile. The material chosen was case- hardened steel-ideal for durability and performance in demanding applications.

What truly set this project apart was LAMOND & MURRAY DEXIS’ ability to deliver a case-hardened and precision-ground gear that met every details of the customer’s requirements . Their technical expertise and attention to detail ensured the gear would perform reliably in its intended environment.

The Result

The customer was highly satisfied – not only with the quality of the finished gear but also with the attractive pricing and lead time. Their confidence in LAMOND & MURRAY DEXIS was reaffirmed, leading to repeat orders for the same part. This project stands as a testament to the company’s commitment to engineering excellence and customer satisfaction.