The Problem

A customer in the steel industry required a gear for a rolling plate mill, a critical component in their production process. The gear needed to be manufactured to precise specifications, with a 16-tooth, 1.75” pitch sprocket. The challenge was to deliver a high-quality, durable gear within a tight 6-week timeframe.

The Solution

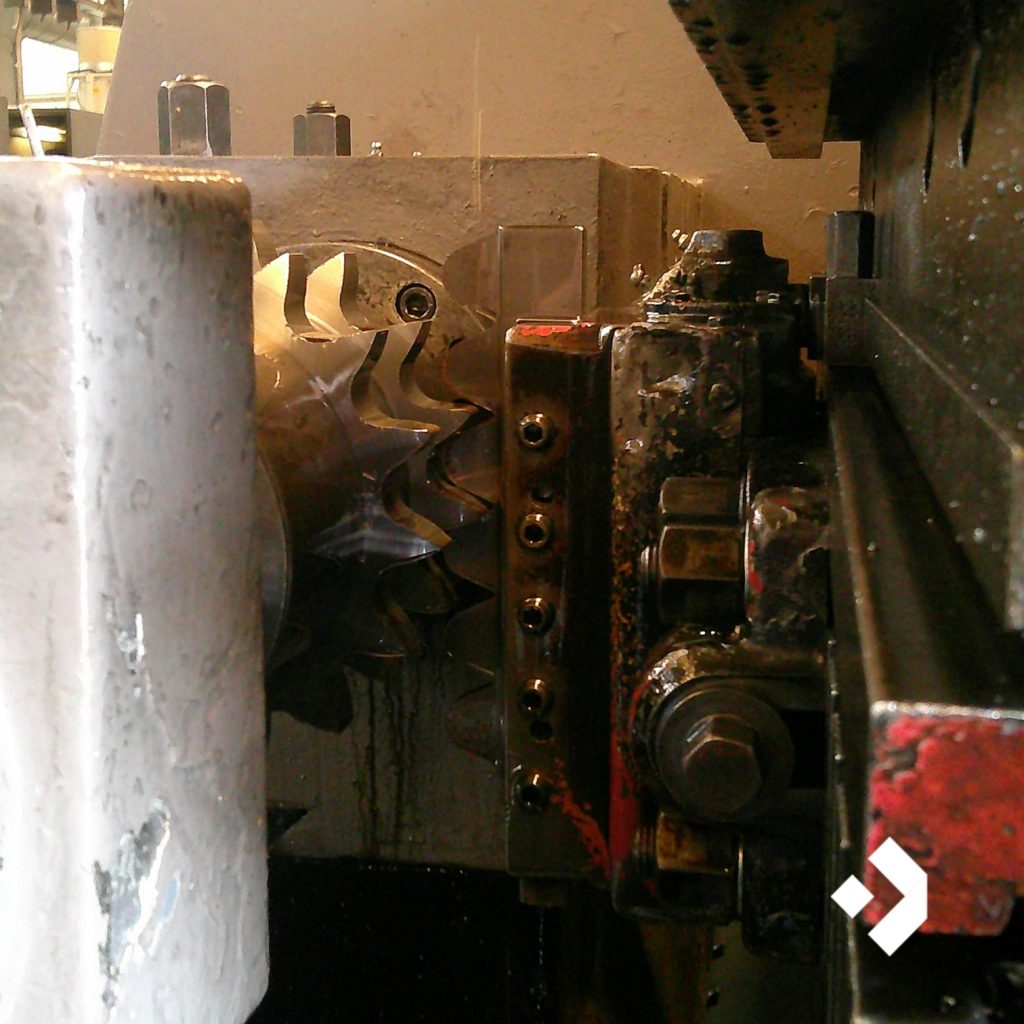

Lamond and Murray were selected for their specialist gear cutting capabilities, particularly their expertise in producing sprockets to exact customer specifications. The team utilised their Sunderland G150 machine to cut the gear, ensuring precision and durability.

What made this project stand out was the versatility of the Sunderland G150, which is capable of cutting sprockets, spur gears, helical gears, and double helical gears—making it an ideal choice for complex and varied gear requirements.

The Result

The project was completed on time and to the customer’s satisfaction, leading to repeat orders for the same part. This case highlights Lamond and Murray’s ability to deliver precision-engineered components that meet the rigorous demands of the steel industry.